What’s Inside an F1 Pirelli Tyre?

Hi, I’m Scott Mansell from driver61, and today I’m going to take this grinder to see what’s inside this Formula One Pirelli tyre. Today I’m at my father’s workshop and they’re racing run and prepare many period Formula one cars from the mid-’90s to around the mid-2000s. This workshop is like a treasure chest of Formula One parts. I’ve dug out this Pirelli Formula One tire, and we’re going to take the grinder to it to see what’s actually inside the carcass of an F1 tyre.

First of all, I’m going to take away some of the rubber on the surface of the tire here to see what’s under the surface and to see what is exposed when we see drivers lock up their wheels and actually go through to the canvas of the tyre.

The first thing is that it’s surprisingly strong and causes a whole load of smoke. If you can just see here, I’ve not really taken much rubber off the tire, and it’s created so much smoke, it’s actually a lot stronger than I expected.

I’m going to carry on and see if I can actually make it through the initial surface of the tire because I haven’t even broken through to any of the treads or the nylon or whatever the material underneath the rubber is that I expect to get to.

As you can now see, there’s a loop of steel that’s in the surface of the tire and that doesn’t seem to be much else. Next up, I’m going to cut directly through the cross section of the tire so we can see each layer of what’s inside the surface, over the shoulder and through the sidewall of the tire just here.

I’ve put a thinner disc in the grinder now and it’s a lot easier to cut. You can see that I’m almost half the way through. I’ll show you some close-ups of this. It’s very interesting, the construction and actually how thin the surface of the tire actually is when you look at it in this cross-section. I’m going to flip the tire over and go in from the other side to finally cut it in half.

What was surprising then was actually the differences in how difficult it was to cut through various sections of the tire. Obviously, here where the bead is on the inside of the tire was very difficult because it’s a steel ring that goes around the inside of the tire. Then as we came through this section, in particular, this shoulder section at the top of the sidewall, it was really, really thin and very easy to cut through. Obviously, there’d be quite a lot of flex in the tire at this point when you see it on track. Then as we come through to the surface here, again, it was quite difficult to cut through.

Almost perfect. I just need to take out one of these more burns, and then the tire will be able to open and we’ll be able to look inside. As you can see, I am absolutely covered in rubber, and there was loads of smoke. I’m really interested to see what’s inside this tire.

There we have it, we have a quarter of the Formula One Pirelli. Now we can see inside the structure, and actually, it’s quite thin. I’ll take the camera now and we’ll have a look.

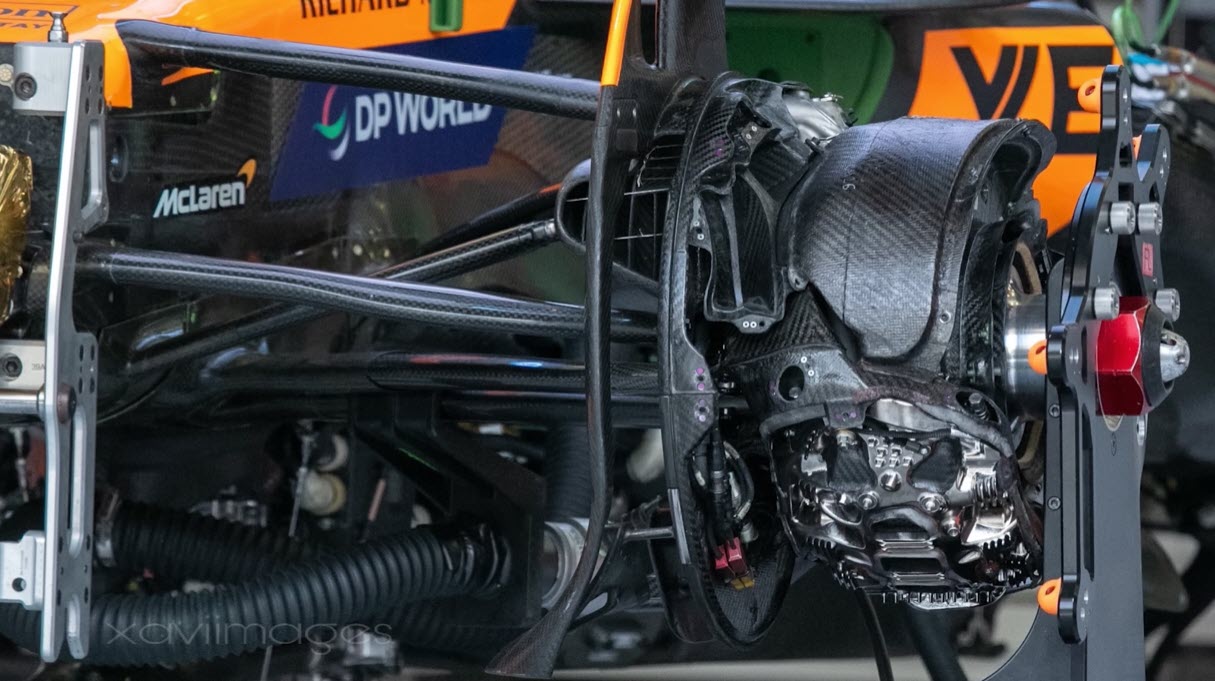

Here we have the cross-section of the tire, you can see first of all the steel bead is just down here this circle cluster of wire here. That runs actually around the inside of the tire like this. It keeps the tire on the wheel and gives it support around that inner edge. Then as we come up the sidewall here, you can see that there’s some radio wire that runs around the sidewall but this is only too dip here and it goes to only one deep here. As we come up to the top of the shoulder of the tire, you can see that there’s actually no wire or no nylon in the tire or as we come through here.

Then on the surface of the tire, we can see that we’ve got the core running across here. Now, I think from the sparks at least, this is steel and there might be some nylon in there but I’m not exactly sure about that. Now again it gives the surface of the tyre some strength.

As you can see here, the actual tread or the sleek part of the tire is only five, four, fimillimetresers thick as we come through here and it’s got the metal running all the way down to the support. It gets a little bit thicker as we get to the end of this coat, that extra row of metal.

Then again, we come to the shoulder which doesn’t have any support. It’s just a rubber. As you can see, it’s really flexible to the top here it’s a lot stiffer when I try to compress it. Of course, the most stiff section is down here near the bid where the tire fits to the wheel.

The ridges that you can see on the inside of the tire here are for when it’s in contact with the side of the wheel on the inside. It’s got ridges down here as well because the breaking forces in an F1 car are so strong and so severe we need to try and give the tire as much grip on the wheel as possible. Otherwise, when the driver gets on the brakes, the wheel can actually slip inside the tire and that causes all sorts of problems such as putting the tire and wheel out of balance so the driver would get a vibration when they’re running quickly along a stretch.

That’s all for this Driver61 video. I know it’s a slightly different style and different topic of video, but if you enjoyed it, please subscribe to the channel and let me know any comments if you do like this style of video. Thank you and see you next time.