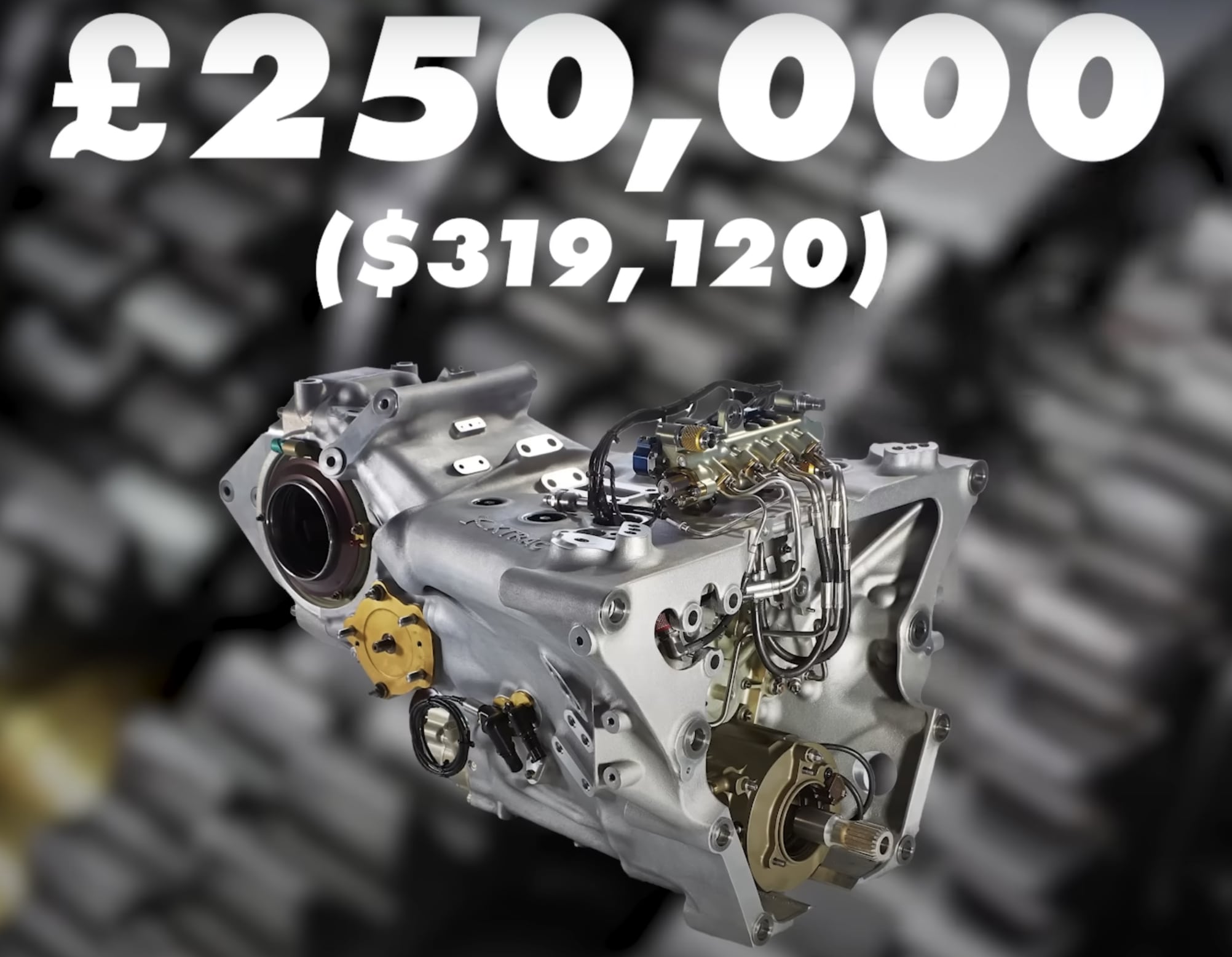

Formula 1 is synonymous with cutting-edge technology, and one of the most complex, expensive components in an F1 car is its gearbox. Costing upwards of £250,000 each and demanding around £7 million in annual spending, these gearboxes are marvels of engineering. Let’s dive into what makes these pieces so crucial and how they differ from conventional gearboxes.

The Stressed Member: How the Gearbox Holds It All Together

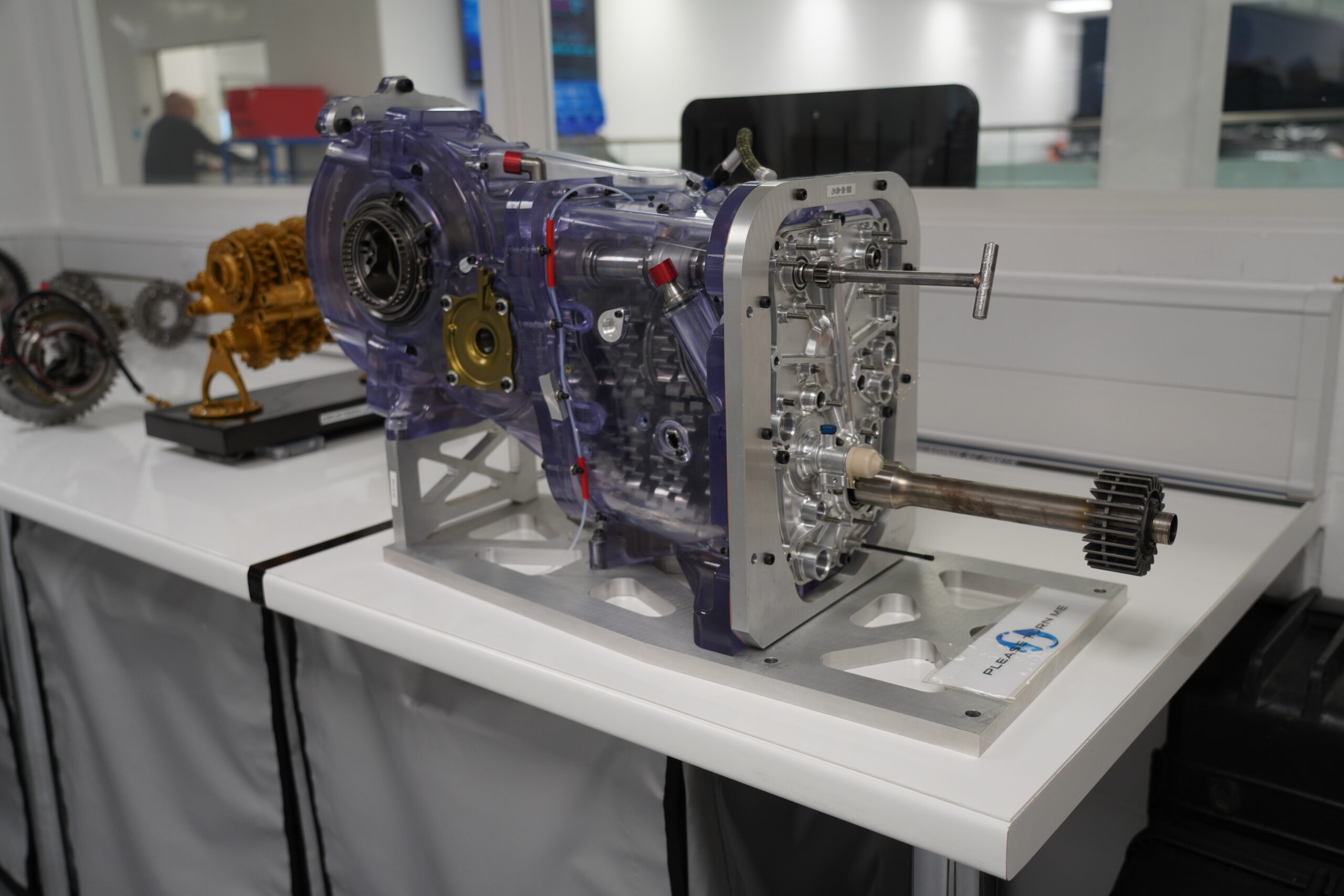

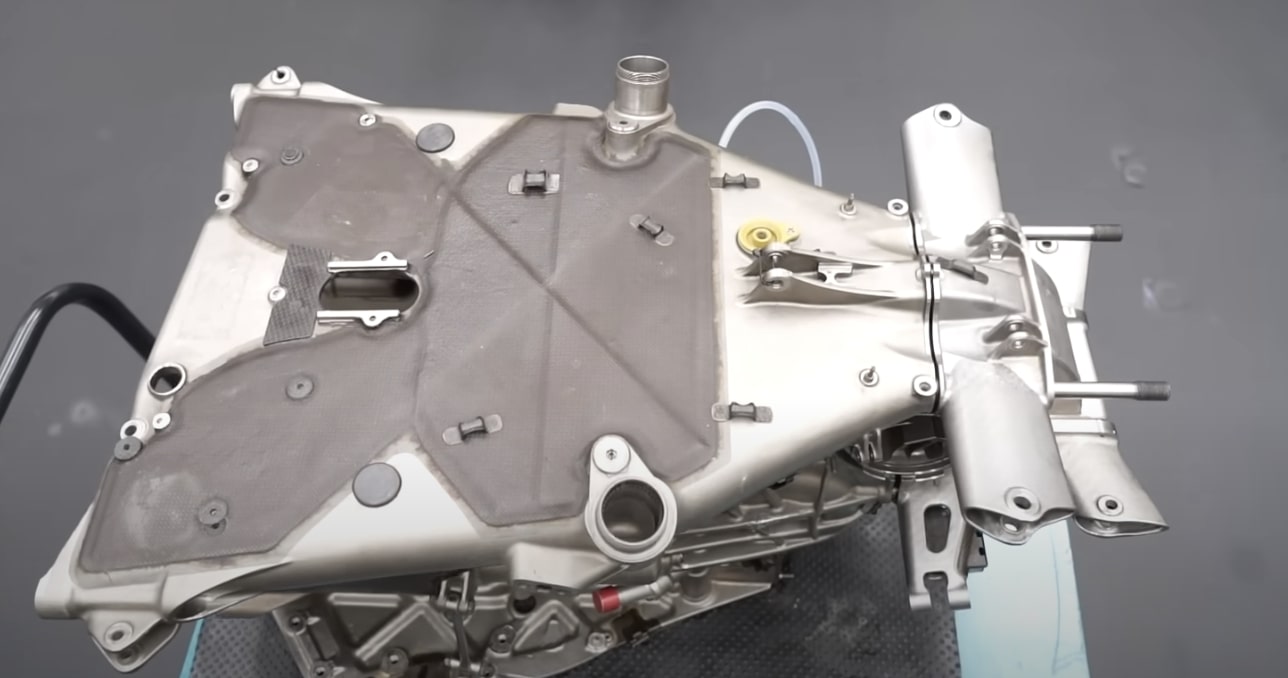

In typical road cars, the engine and gearbox are bolted onto a chassis – the backbone that provides structural integrity. However, in an F1 car, the gearbox isn’t just bolted on; it’s a stressed member. In this configuration, the gearbox acts as a structural part of the car, holding the vehicle together from engine to rear crash structure.

This engineering approach began in the 1960s with visionary designers who realized that making the engine and gearbox structural components reduced weight and increased strength. Today, the F1 gearbox’s casing must endure significant stress and serve as the mounting point for critical parts like the suspension. Remarkably, despite this strength, the casing is incredibly thin, a testament to the lightweight materials used and precise engineering involved.

Material Mastery: Lightweight and Strong

F1 gearboxes are crafted from advanced materials like 3D-printed titanium and carbon fibre. The combination achieves a balance of strength and lightness, with titanium providing durability and carbon fibre reducing weight where possible. Specific sections of the titanium are machined out to be replaced by carbon, demonstrating the meticulous attention to every gram – a necessity in F1’s weight-sensitive design process.

Beyond Gears: What’s Inside the Gearbox Casing?

Inside an F1 gearbox, you’ll find more than just gears. The gearbox contains the clutch, differential gears, and a hydraulic differential that work together to transfer power efficiently. The entire setup ensures power from the engine reaches the wheels with precision. Oil pumps and hydraulic systems maintain optimal conditions, lubricating gears and keeping temperatures under control as the car races.

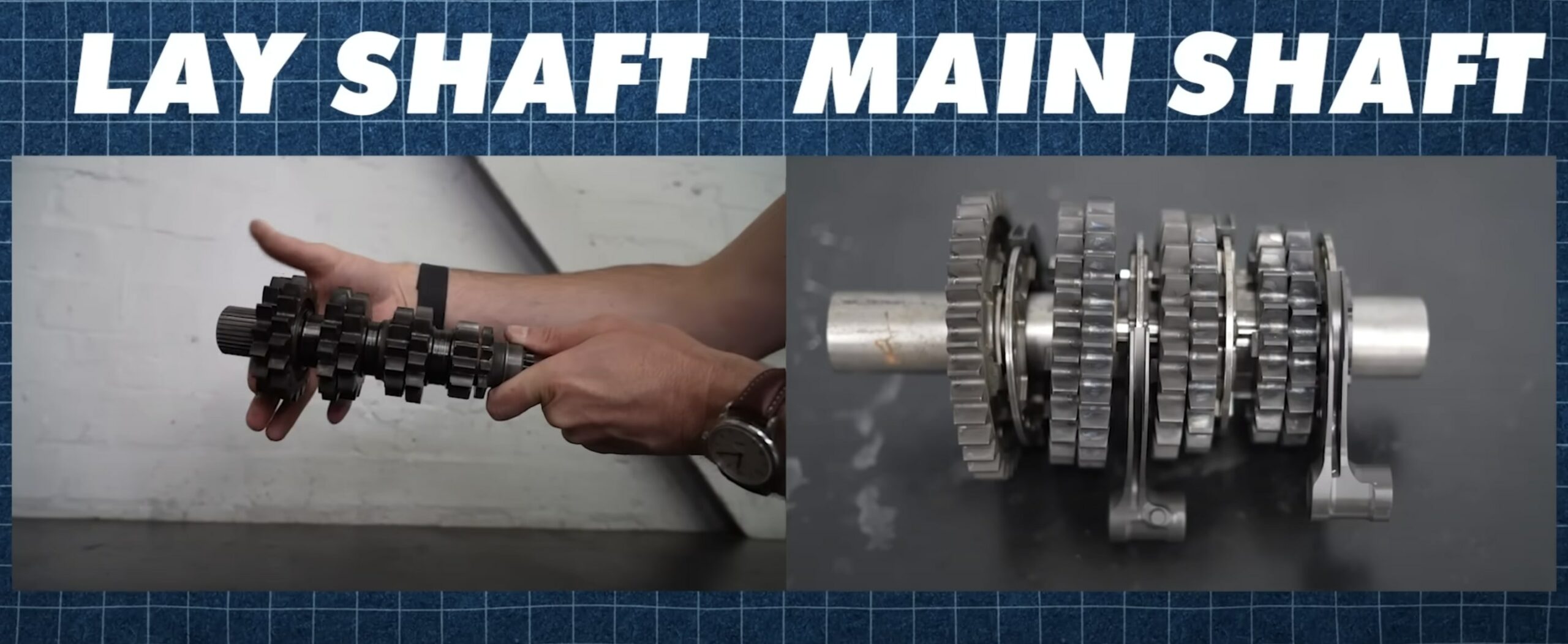

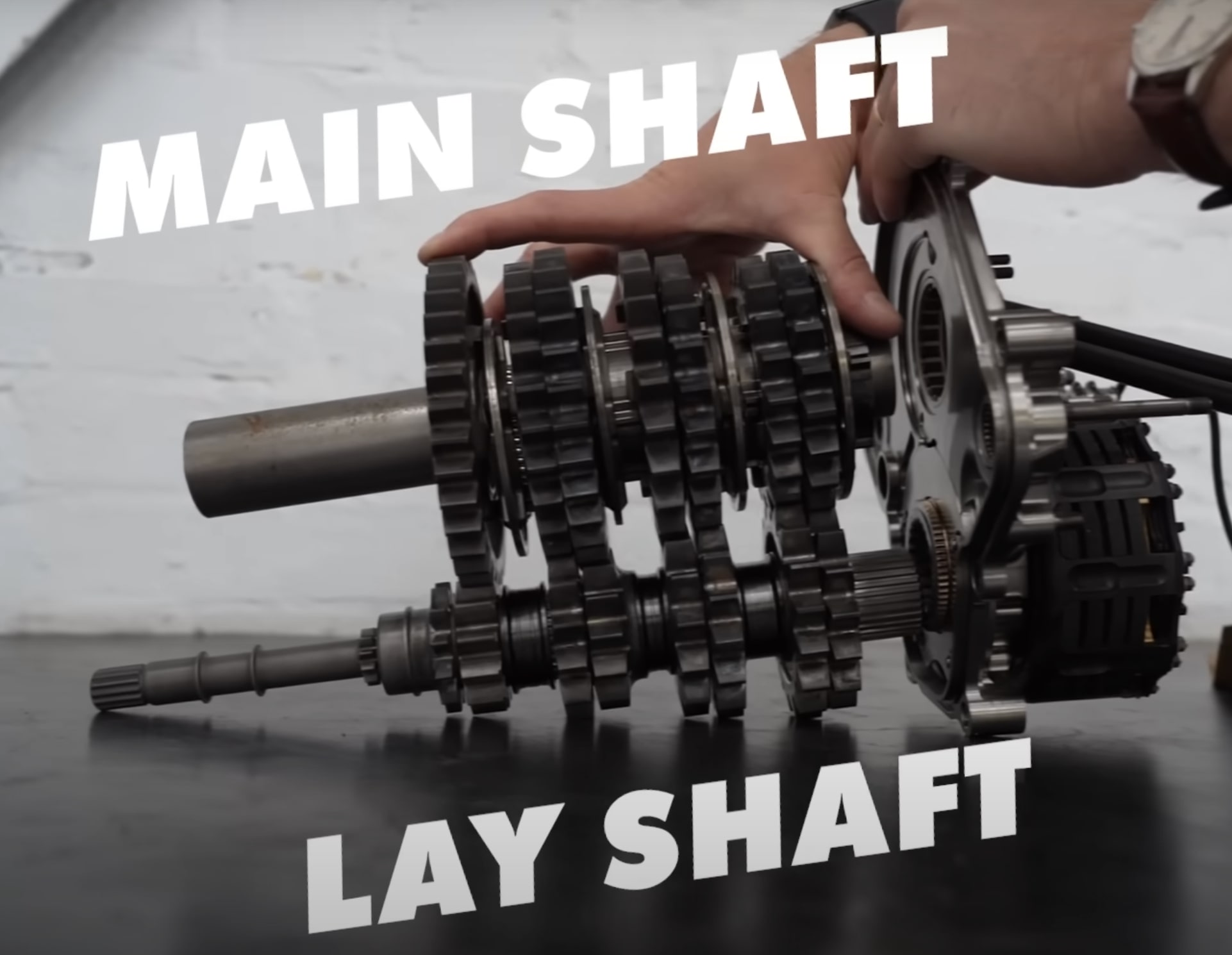

The layout includes two shafts: the lay shaft and the main shaft. The lay shaft is driven by the engine, and its connected gears ensure power flow. The main shaft, however, only spins once a gear is selected, and this separation allows the gearbox to run efficiently without unnecessary friction.

Seamless Shifts: How F1 Drivers Shift in Milliseconds

One of the standout features in modern F1 gearboxes is the seamless shift mechanism, which enables gear changes with no interruption to power delivery. While traditional gearboxes require the previous gear to disengage before the next one can engage, F1 gearboxes use two selector barrels. With this dual-barrel design, one barrel can prepare the upcoming gear while the other engages or disengages the current gear. This system reduces shift times to an astonishing 2 to 4 milliseconds.

Although this technology enhances performance, it comes with risks. If two gears engage simultaneously, the gearbox can lock and potentially explode, demonstrating how high-stakes F1 engineering can be.

Why Reverse is Different

Unlike road cars, F1 gearboxes treat reverse as an afterthought. Reverse gears are light and thin, reflecting their limited use. F1 cars rarely need to reverse, and when they do, it’s typically in the pits at low speed. This lightweight approach minimizes weight without sacrificing critical performance in forward gears.

Engineering Precision at Every Level

Looking inside an F1 gearbox, the design optimizes every component for minimal weight and maximal strength. Gear teeth, hubs, and selector barrels are shaped with holes and cuts to shave off any excess material. Even small adjustments, like triangular shapes instead of squares, help reduce weight.

In the competitive world of F1, these optimizations add up. Each decision, from materials to layout, contributes to a gearbox that can handle extreme loads, shift seamlessly in milliseconds, and still weigh as little as possible.

Conclusion: The Cost of Perfection

F1 gearboxes embody the pinnacle of automotive engineering. With their role as stressed members, their seamless shifts, and their meticulous design, it’s no wonder they cost £250,000 each. This isn’t just a component; it’s a testament to the ingenuity and attention to detail that make Formula 1 the premier motorsport.

F1 gearboxes might not be something fans can easily see, but their impact on the car’s performance is undeniable. Understanding what goes into these engineering marvels sheds light on just how much work and precision goes into every millisecond on the track.