Why Pushing Engines Beyond 20,000 RPM is Almost Impossible

In motorsport engineering, few concepts are as captivating as the race to rev higher. While most cars today operate far below 10,000 RPM, Formula 1 once saw engines soaring up to 20,000 RPM. But after hitting this peak, engineers faced a fundamental question: why can’t engines rev any higher? Understanding the physical, mechanical, and thermal limits that stop engines from reaching 21,000 RPM reveals the impressive, almost insurmountable engineering challenges behind extreme RPMs.

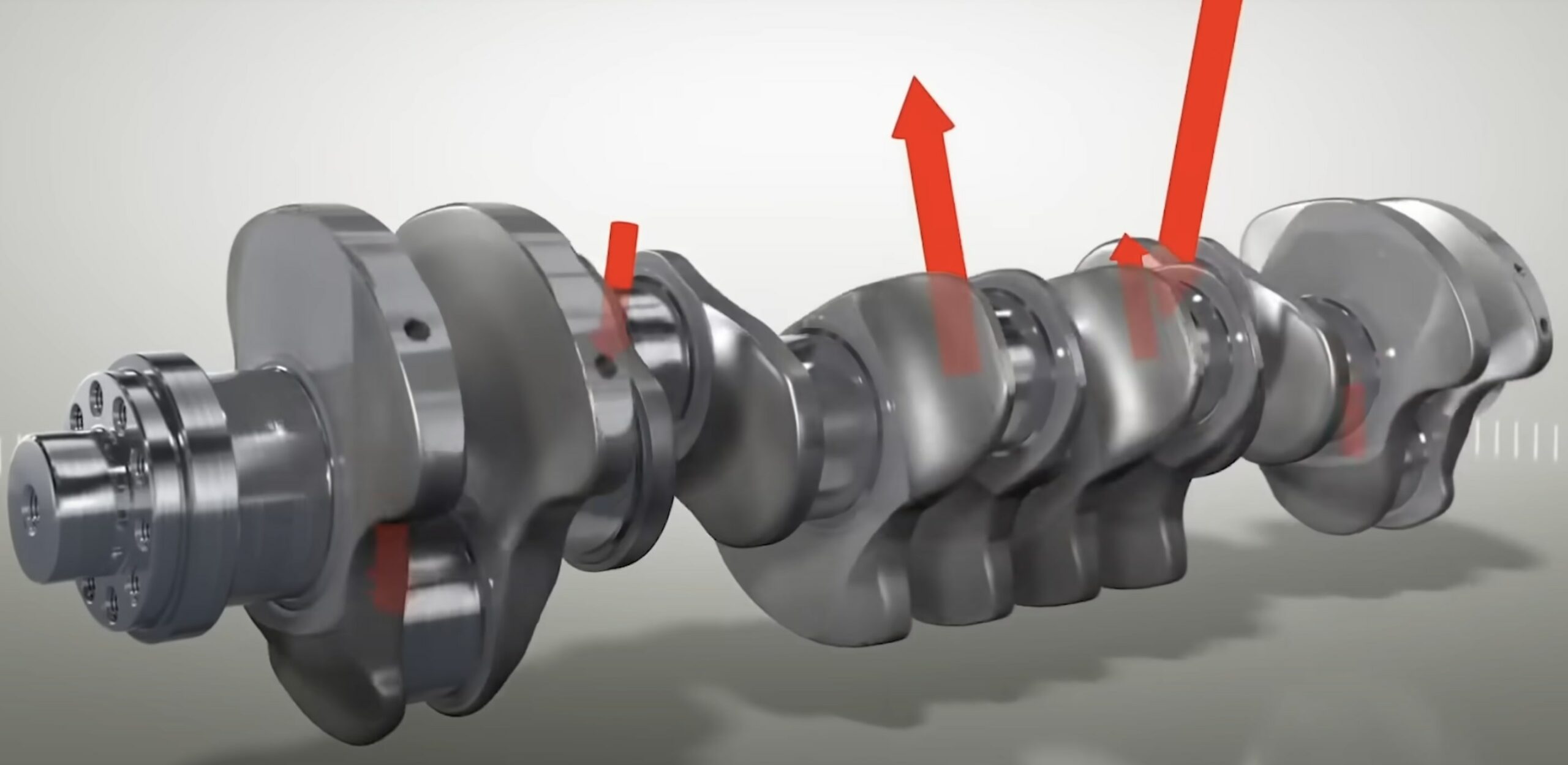

The Importance of RPM in Formula 1

In motorsport, RPM isn’t just a number – it’s a factor that directly influences power output. RPM, or revolutions per minute, is how often the crankshaft spins in 60 seconds. A higher RPM typically means more power, translating to faster lap times. As Maria, head of Powertrain Engineering at IFP School in France, explains, power depends on both RPM and torque, establishing a close relationship between revolutions and raw speed. However, despite the advantages, Formula 1 and most engines hit a ceiling at 20,000 RPM.

The History of RPM Limits in F1

Formula 1 once had no RPM restrictions, allowing engines to push towards 20,000 RPM, as with the 2006 Cosworth CA engine. But as costs escalated, the FIA capped RPM at 19,000 in 2007, later dropping it to 15,000 when hybrid engines were introduced. Today, the limit is lifted, but even with this freedom, teams rarely exceed 13,000 RPM. Why? Because the physical barriers to achieving higher RPMs are greater than many anticipate.

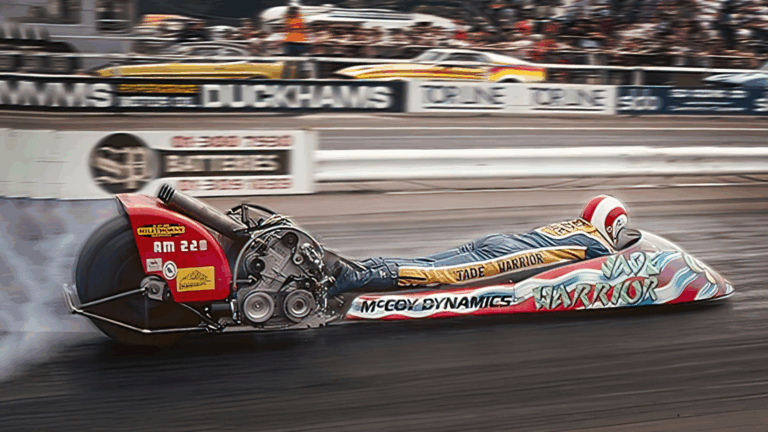

Two-Stroke vs. Four-Stroke Engines: Why F1 Sticks with Four-Strokes

Two-stroke engines can theoretically rev higher than four-strokes, with fewer steps in each power cycle. They complete the intake, compression, power, and exhaust cycles in just two strokes instead of four, offering a power stroke for every crankshaft revolution. However, they are less fuel-efficient and pollute more, burning oil with fuel. Formula 1 engineers need the durability, efficiency, and power density that four-stroke engines provide.

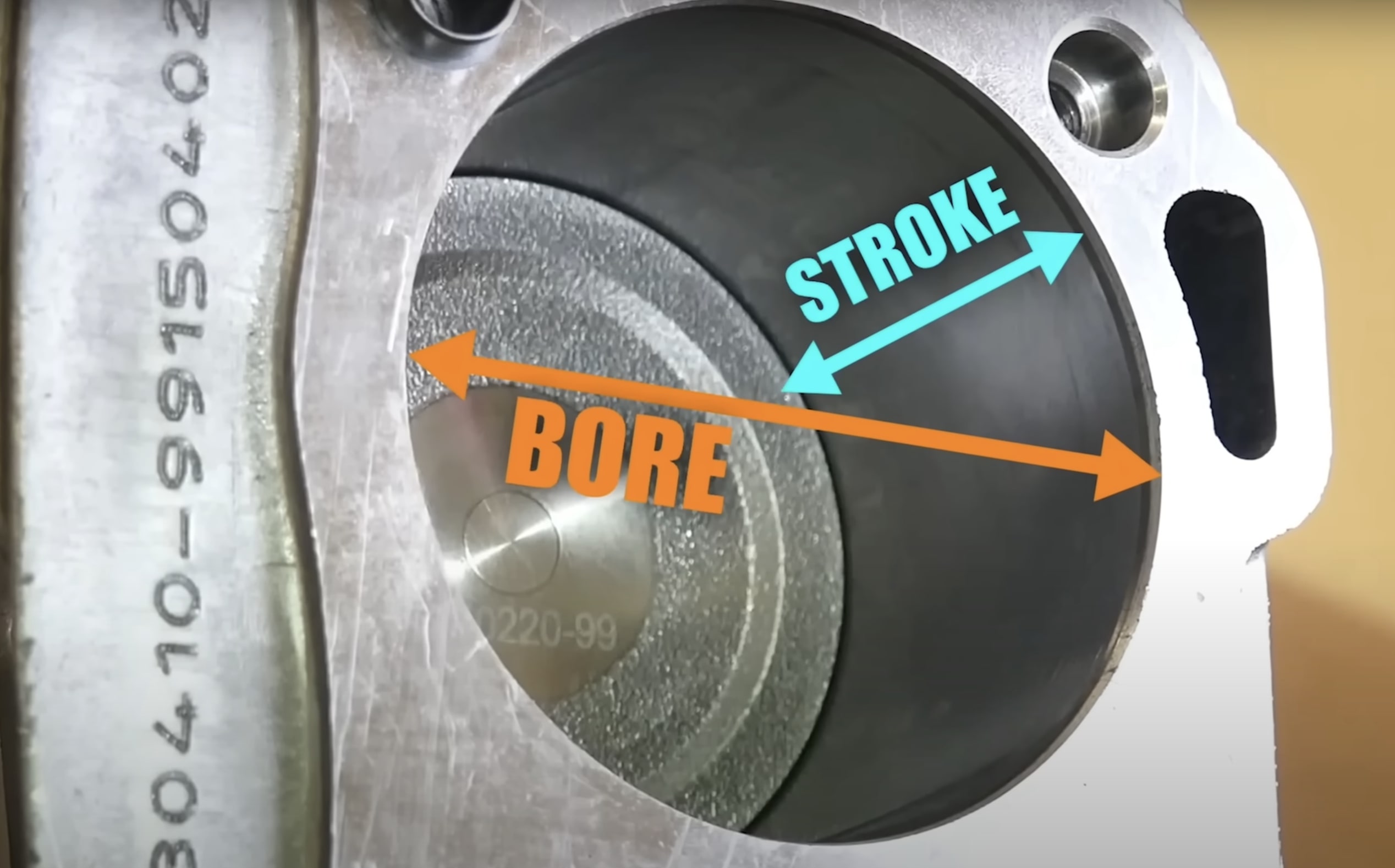

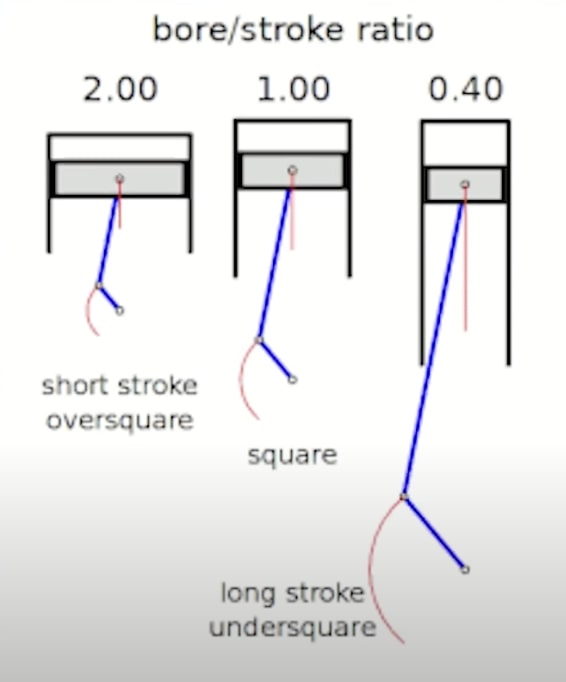

The Role of Bore-to-Stroke Ratio in RPM Limits

A critical factor that limits RPM in four-stroke engines is the bore-to-stroke ratio, which determines the distance a piston travels with each cycle. In F1, this ratio is typically over-square – meaning a wider bore and shorter stroke. Shorter strokes limit the distance pistons travel, allowing for higher RPMs without excessive piston speeds. This reduction in piston travel distance enables F1 engines to generate high power while managing extreme stresses.

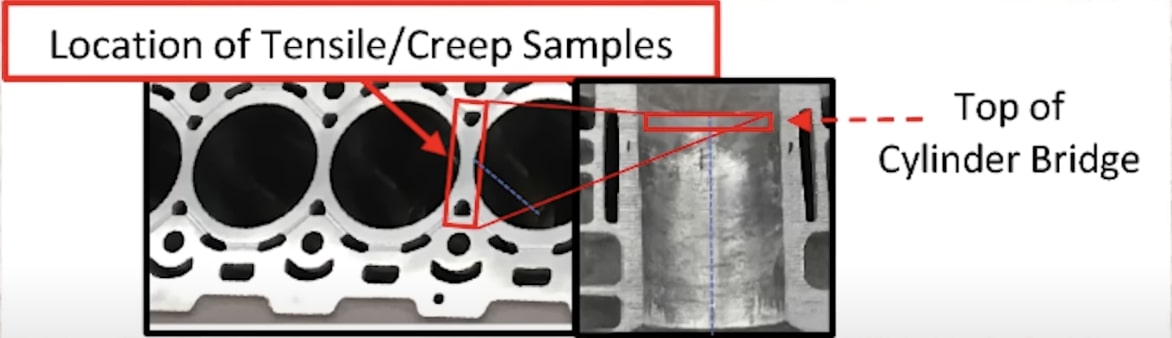

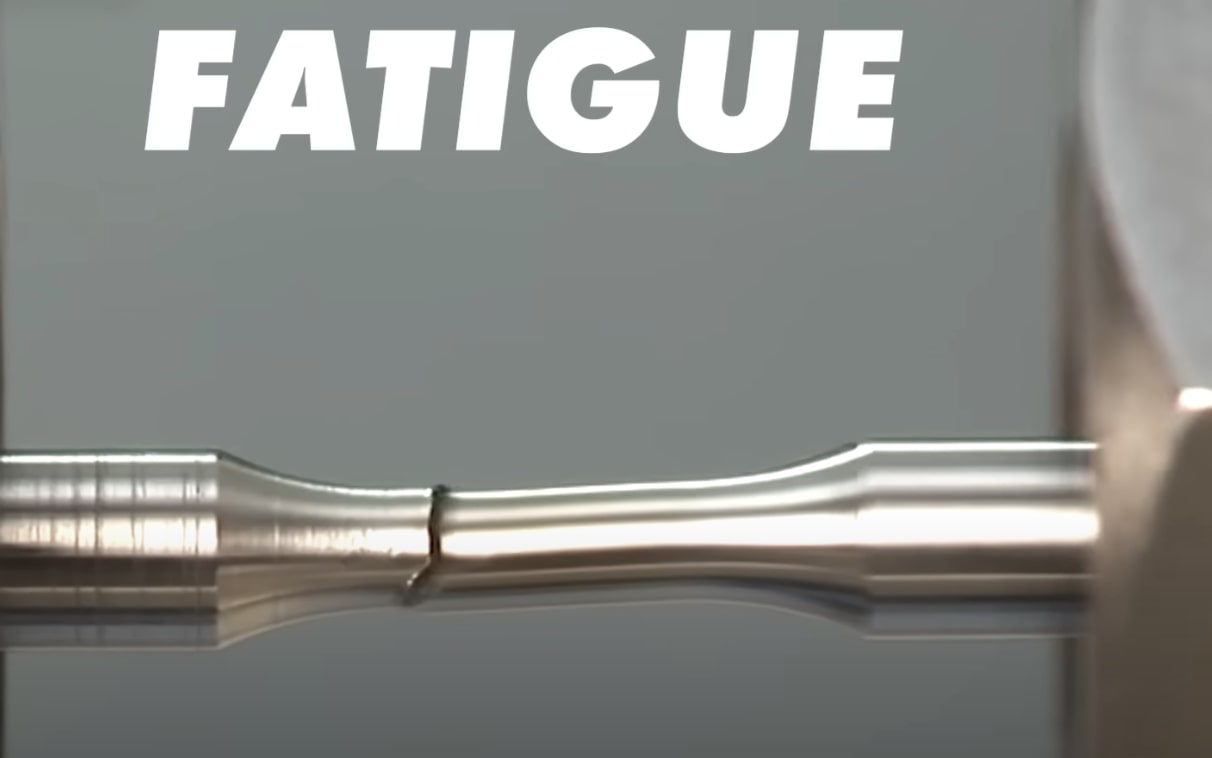

Mechanical Stress and Creep in High-RPM Engines

Mechanical stress in high-RPM engines is a formidable challenge. As pistons move at high speeds, parts are subjected to forces that can cause deformation. In particular, F1 engines face two major issues: creep and fatigue failure. Creep happens when engine parts gradually change shape under extreme, repetitive stress. Fatigue failure occurs as microscopic stresses accumulate with each rotation, potentially leading to cracks and material fractures. To combat these, F1 engines use reinforced materials like aluminum and titanium alloys, which are lightweight, strong, and resistant to fatigue and heat.

Valve Timing and the Advantage of Pneumatic Valves

Traditional valves struggle to keep up at extreme RPMs because they may not close quickly enough, risking contact with rising pistons. In 1986, F1 introduced pneumatic valves, which use compressed air to quickly close valves and prevent piston-valve collisions. Pneumatic valves allow engines to rev higher than traditional spring valves, yet even they encounter issues at extreme speeds, where heat, stress, and wear remain challenging.

Combustion Limits: The Importance of Air-Fuel Mixing

As RPM increases, maintaining effective combustion becomes more difficult. Proper air-fuel mixing is essential for even ignition. In a four-stroke engine at 20,000 RPM, the entire intake, compression, combustion, and exhaust cycle happens in just 0.3 seconds. This rapid cycle time restricts the time for air and fuel to mix effectively. An uneven mix can create hot spots or areas with too much or too little fuel, leading to incomplete combustion, engine damage, and lower RPMs.

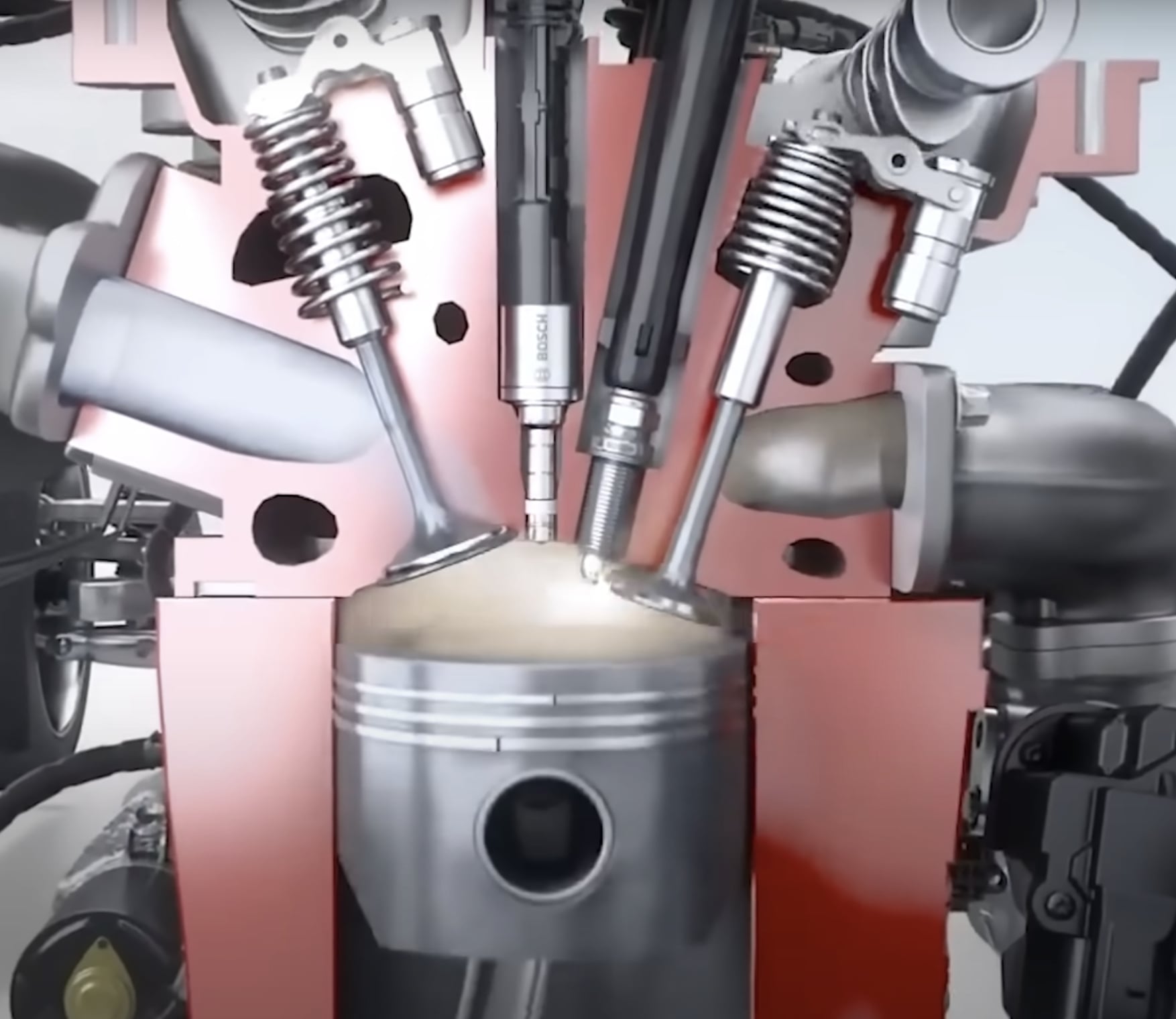

Turbulent Jet Ignition: A Breakthrough in Combustion Efficiency

In 2015, Formula 1 adopted Turbulent Jet Ignition (TJI), a technology that improves combustion efficiency by creating multiple ignition points within the combustion chamber. In TJI, a small pre-chamber above the cylinder ignites a small fuel-air mixture, which then jets into the main chamber, igniting the entire air-fuel mix more evenly. This even distribution reduces hot spots and improves engine efficiency, enabling higher RPMs while managing the thermal stresses within the combustion chamber.

Beyond Material Strength: Why 21,000 RPM Remains Out of Reach

While TJI and reinforced materials have enabled F1 engines to reach high RPMs, the combined limitations of mechanical stress, heat management, and air-fuel mixing create an insurmountable barrier. Even with cutting-edge engineering, these physical constraints mean that achieving a consistent 21,000 RPM remains out of reach, reinforcing the marvel of modern motorsport engineering.