How An F1 Gearbox Works (I went to the factory)

Formula 1 gearboxes are a marvel of modern engineering. They handle over 1,000 horsepower, execute more than 4,000 gear shifts during a single Grand Prix, and carry the entire load of the car’s rear suspension – all while weighing just 40 kilograms. At Alpine F1, this critical component of the drivetrain is crafted to perfection, balancing performance, durability, and the ever-present need to shave off every unnecessary gram.

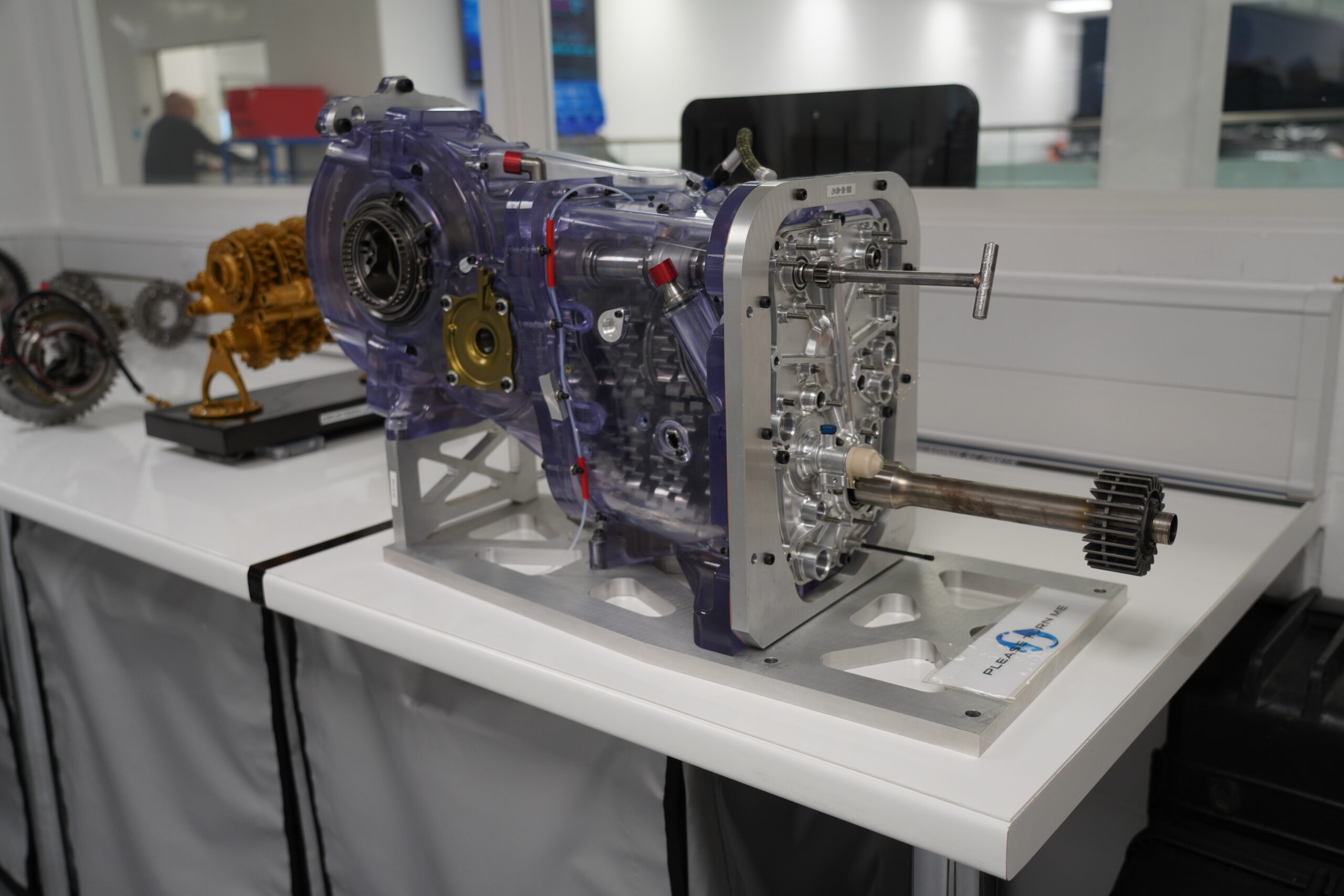

Recently, Alpine provided exclusive behind-the-scenes access to their cutting-edge development gearbox. This unique unit features a see-through casing used for oil flow testing, an essential part of preparing for the sport’s ever-evolving regulations. Here’s an in-depth look at how F1 gearboxes work and why they represent some of the most intricate engineering in motorsport.

What Is an F1 Gearbox, and Where Does It Sit?

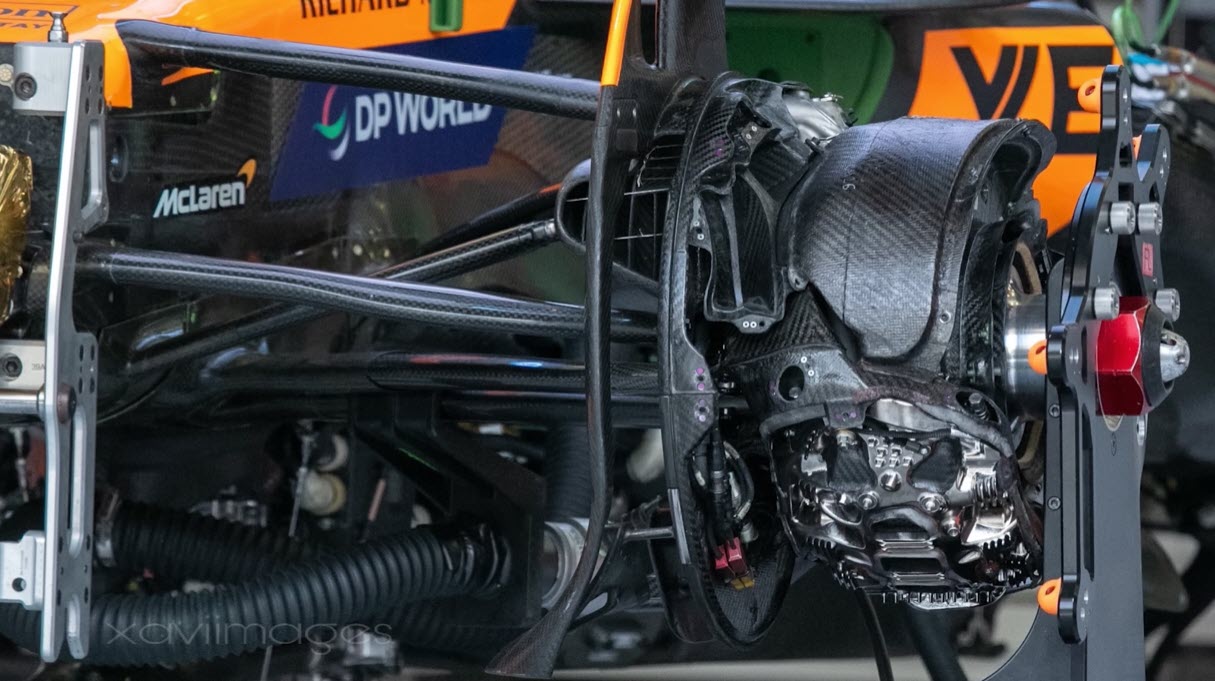

The gearbox in a Formula 1 car is housed in a casing bolted directly to the engine. This casing also supports the entire rear suspension, placing it between the engine and the differential. The placement is not only essential for structural integrity but also for the aerodynamic profile of the car.

The see-through casing used in Alpine’s development gearbox allowed engineers to study the flow of oil in real time. This process was critical during the development of their 2022 car, ensuring every component received proper lubrication.

Why Oil Flow Matters

Oil flow is vital to the longevity and performance of an F1 gearbox. Insufficient lubrication leads to heat buildup, excessive wear, and ultimately catastrophic failure – potentially costing the team a race. The oil pump, driven by the speed of the gearbox, ensures a consistent flow of oil that increases with the gearbox’s speed.

To test this, Alpine ran the gearbox on a dyno, simulating various conditions to study the oil’s behavior. While software simulations can provide theoretical insights, real-world testing remains indispensable to validate the system’s performance.

The Inner Workings of an F1 Gearbox

Power from the engine enters the gearbox through a drive shaft and is distributed to the wheels via a complex arrangement of gears and shafts. In an F1 car, the gears are not arranged sequentially from first to eighth. Instead, lower gears are positioned closer to the bearings, where they can handle higher torque, while higher gears sit further away, reducing stress on the shaft.

Each team is limited to five driveline assemblies per season, including all gearbox components, before penalties apply. This regulation means gearboxes must last approximately 3,000 miles – an enormous demand given the intense forces and heat they endure during races.

Precision Meets Performance

Modern F1 gearboxes feature over 500 components packed into their lightweight casings. They must strike a perfect balance between strength and weight. As the legendary Colin Chapman once said, “Adding power makes you faster on the straights; subtracting weight makes you faster everywhere.” This philosophy is evident in every aspect of F1 gearbox design.

Interestingly, the reverse gear – a mandatory feature in F1 – is rarely used during races. When it is, drivers must navigate several menu layers in the car’s software to engage it, highlighting its limited role in overall performance.

Oil Circulation and Cooling

The gearbox’s oil circulation system is straightforward yet effective. Oil is pumped from a reservoir at the bottom of the casing, sprayed onto the gears via a spray bar, and circulated back through the system. This constant flow ensures every component remains lubricated and cool, even under extreme conditions.

At Alpine, a single oil pump handles about a litre of oil, demonstrating the efficiency required to maintain performance at the highest level of motorsport.

The Role of the Differential

One of the more complex elements of an F1 gearbox is the differential, which allows the rear wheels to spin at different speeds – a crucial feature for navigating corners efficiently. Unlike a road car, the F1 differential includes a clutch mechanism that can lock the wheels together under acceleration, providing better traction out of corners.

The differential is controlled hydraulically, enabling drivers to adjust its settings on the fly, depending on the cornering demands of each section of the track.

Why F1 Gearboxes Are So Expensive

With a price tag exceeding $6 million annually, F1 gearboxes represent an enormous investment for teams. This cost reflects the relentless pursuit of performance, as well as the precision engineering and materials required to handle the extreme demands of modern Formula 1.

Each component is meticulously designed, tested, and manufactured to withstand incredible forces while maintaining a minimal weight. The result is a masterpiece of engineering that exemplifies the sport’s mantra: performance above all else.