Uncovering F1 Braking Technology: The Mechanics Behind Formula 1 Brakes

Formula 1 braking systems are marvels of engineering, designed to bring a car traveling over 200 mph to a near standstill within seconds. This feat subjects the driver to nearly 6G in deceleration, enough to test even the most experienced athletes. But what makes F1 brakes capable of such intense stopping power? Let’s dive into the technology, guided by the Alpine F1 team, to understand the incredible mechanics behind F1’s braking systems.

Why F1 Brakes Matter

In F1, every millisecond counts. Braking late allows a car to gain crucial seconds, making brake performance pivotal. For example, if two cars are racing at 200 mph, and one car brakes just 10 metres later than the other, it gains 0.078 seconds. Although small, this difference could be decisive, and F1 teams invest millions to optimise every aspect of braking.

The Force Behind the Brake Pedal

An F1 driver exerts a staggering 180 kg of force on the brake pedal. This isn’t your average car pedal; it’s made from a single piece of carbon fibre to maintain strength without adding weight, with each pedal customized to the driver’s foot. Such force transmits through the master cylinder to convert the pedal pressure into hydraulic power, initiating the braking action.

Master Cylinder and Brake-by-Wire

Modern F1 cars have a tandem master cylinder, handling both front and rear brakes simultaneously. This setup is paired with a brake-by-wire system, which adjusts the braking pressure based on real-time data. The ECU takes over the rear braking pressure during energy recovery, reducing the risk of rear lock-up, which can destabilise the car. Maintaining this balance is critical for driver confidence, allowing precise brake application even in split-second decisions.

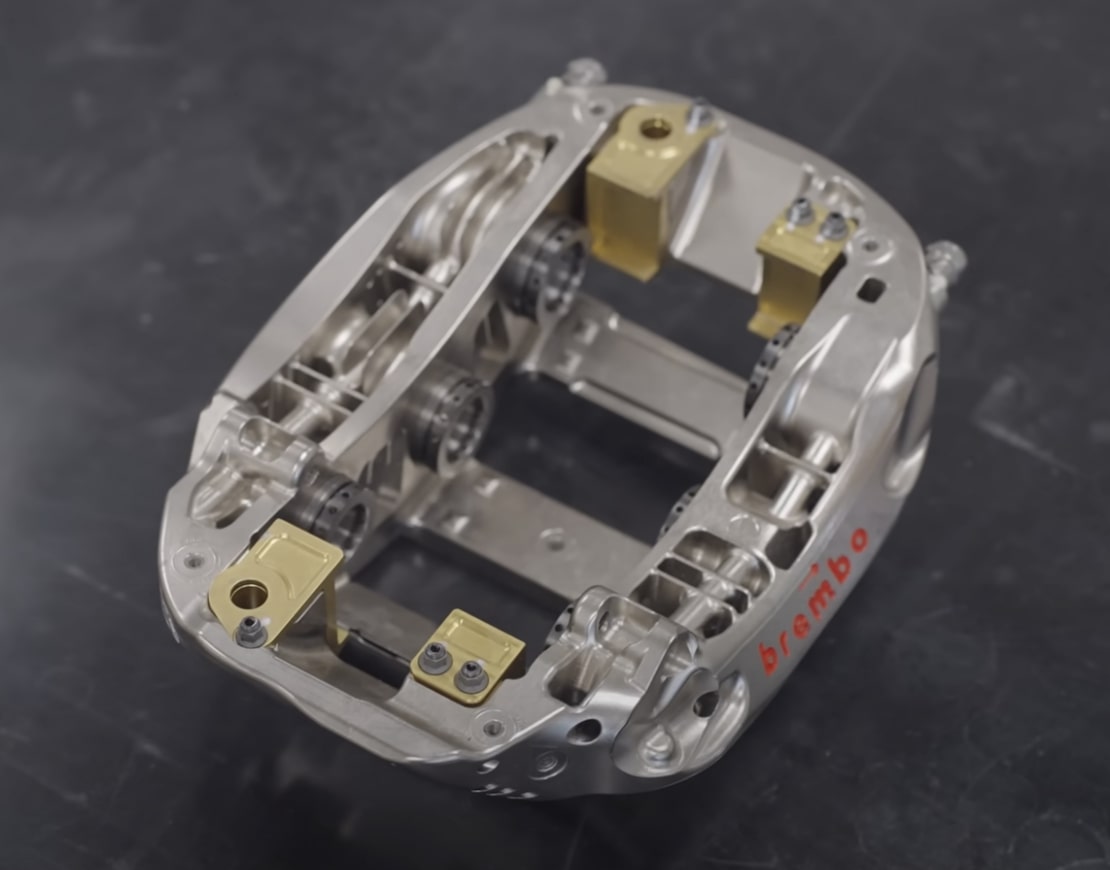

Hydraulic Lines and Calipers

From the master cylinder, brake fluid travels through Hardline pipes and braided steel hoses. The Alpine F1 team prefers Hardline pipes where possible, as they provide rigidity and minimise expansion under pressure. However, for flexibility – especially as the calipers move with suspension – braided hoses are employed. The calipers themselves are high-strength alloy, designed to withstand the enormous heat and pressure generated during braking.

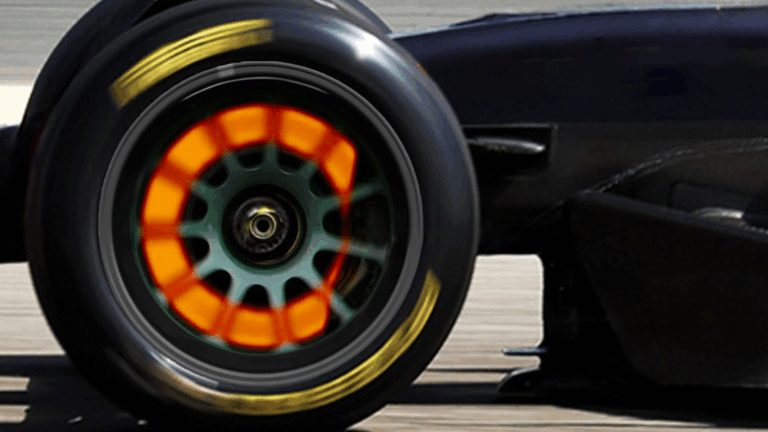

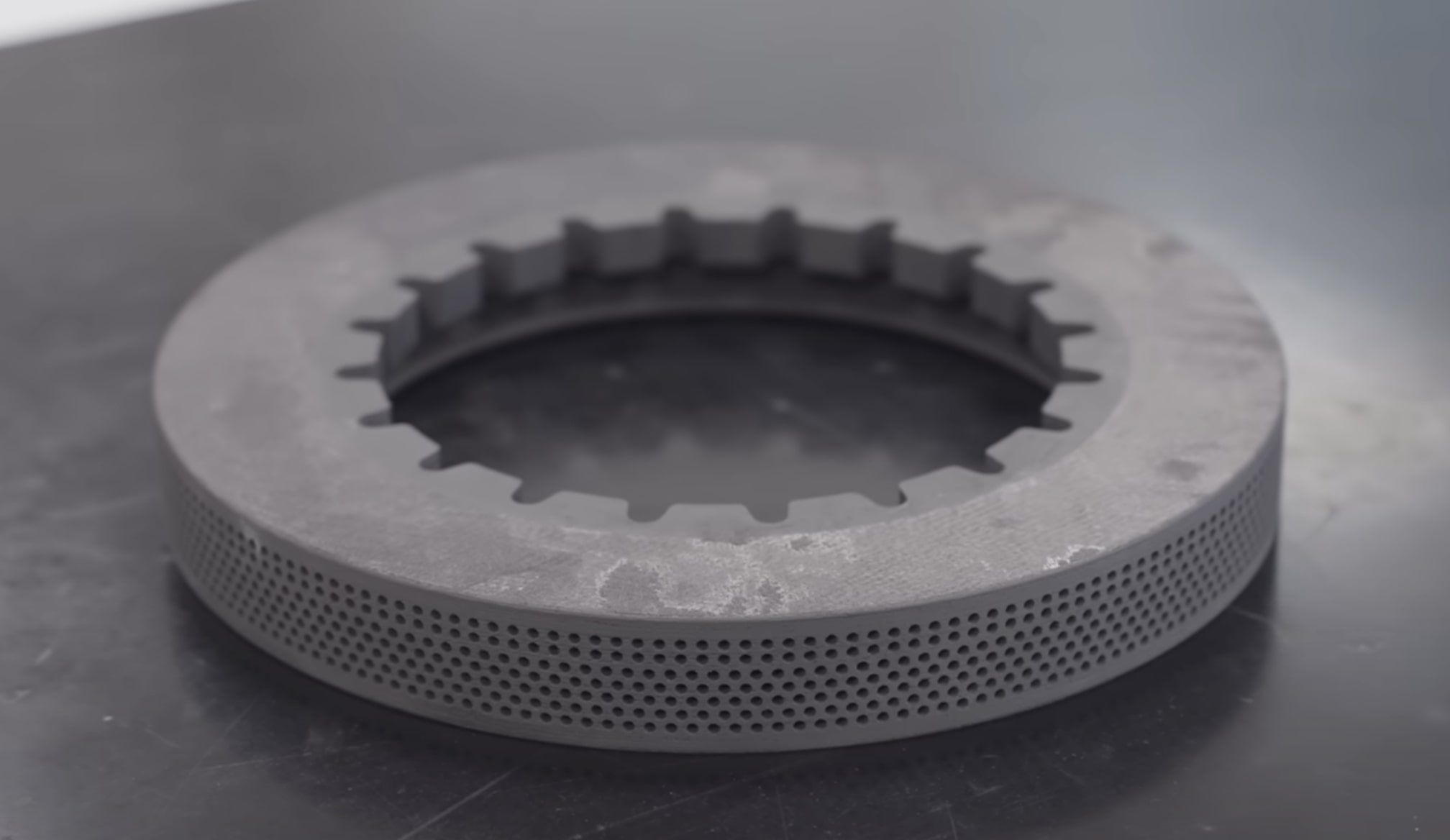

Carbon-Composite Discs

Formula 1 brake discs are crafted from carbon composite material, designed to endure temperatures exceeding 1,000° C. These discs have thousands of drilled holes to increase surface area, allowing heat to dissipate faster. The larger brake discs now used with 18-inch wheels provide added leverage, making it easier to decelerate rapidly. Due to wear and tear, Alpine typically replaces these discs after each race weekend.

The Role of Brake-by-Wire in Energy Recovery

Energy recovery has transformed F1 braking, adding complexity to the rear brakes. Brake-by-wire systems adjust rear braking pressure, balancing it with the energy recovered by the MGU-K (Motor Generator Unit-Kinetic). This means that instead of physical pressure from the pedal, the ECU can modify brake application to match energy needs, maintaining stability and optimising speed.

Conclusion

The braking systems of Formula 1 cars, exemplified by Alpine F1’s approach, are testaments to engineering precision and innovation. These brakes allow F1 drivers to control deceleration at incredible speeds, balancing physical demands and the need for precise stopping power. As F1 evolves, so does braking technology, continually pushing the boundaries of what’s possible on the track.