When it comes to motorsport innovation, rallying often leads the charge, pushing boundaries in ways circuit racing rarely dares. Among its most iconic advancements is the anti-lag system (ALS), a technology that not only sounds incredible but fundamentally changed how rally cars deliver power.

The unmistakable pops, bangs, and flames shooting from rally car exhausts aren’t just for show—they’re the soundtrack of a turbocharger working overtime.

What is Anti-Lag?

Anti-lag is a system designed to maintain turbo boost pressure even when the driver lifts off the throttle. Normally, turbochargers depend on exhaust gases from the engine to spin and create boost. Without constant throttle input, the turbo slows, causing the dreaded “lag” when the driver accelerates again. In rallying, where quick response and power delivery can make or break a stage, turbo lag was a significant problem.

The solution? Burn fuel directly in the exhaust to keep the turbo spinning. It’s a simple concept with complex execution, and its development during the early 2000s turned rally cars into fire-breathing beasts.

The Rules That Shaped the Tech

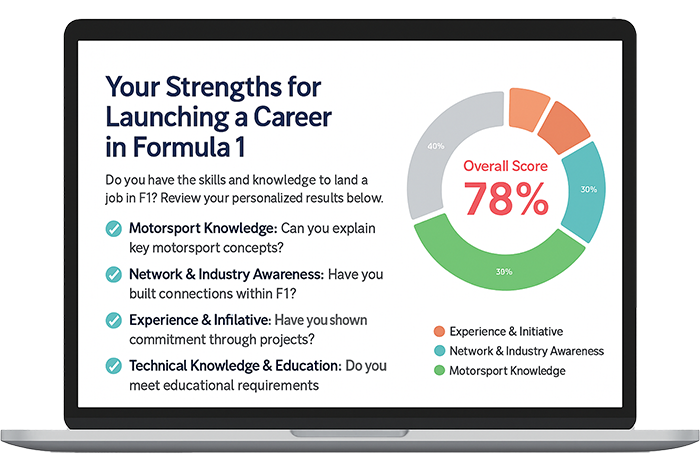

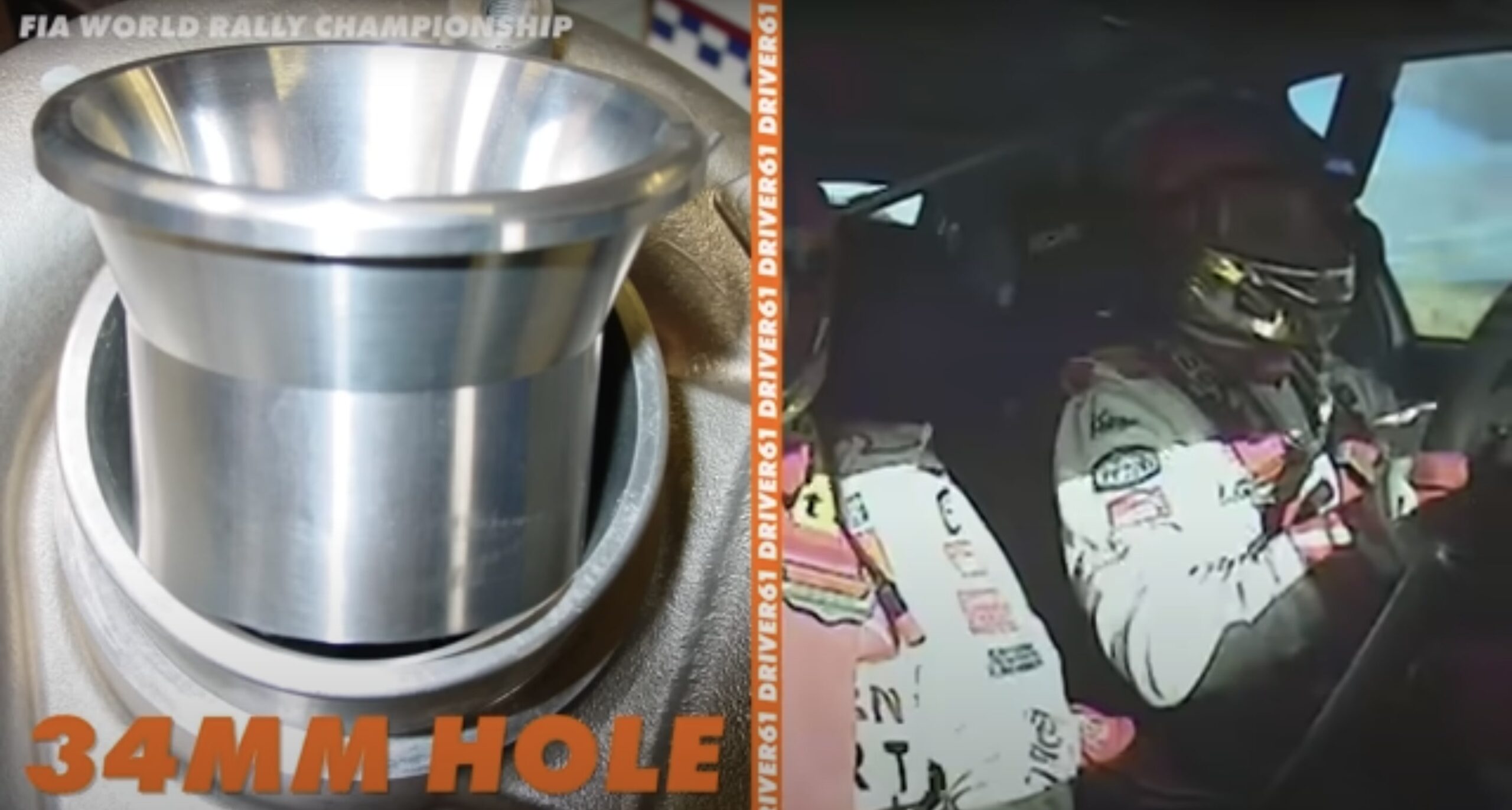

In the early 2000s, rallying faced strict regulations. All cars had to stick to a 2-litre engine limit, but turbochargers were relatively unrestricted. Teams exploited this by bolting on massive turbos, generating upwards of 400 horsepower. However, the FIA introduced restrictor plates – precisely 34mm in diameter – to limit the amount of air entering the turbo. This capped power to around 300 horsepower but created additional turbo lag since the restricted air made it harder for turbos to generate boost.

Clever Solutions: From Twin-Charging to Anti-Lag

Before ALS, manufacturers explored various methods to combat lag. Lancia pioneered twin-charging, using both a supercharger and a turbocharger to deliver boost across the rev range. While effective, this setup added weight and complexity.

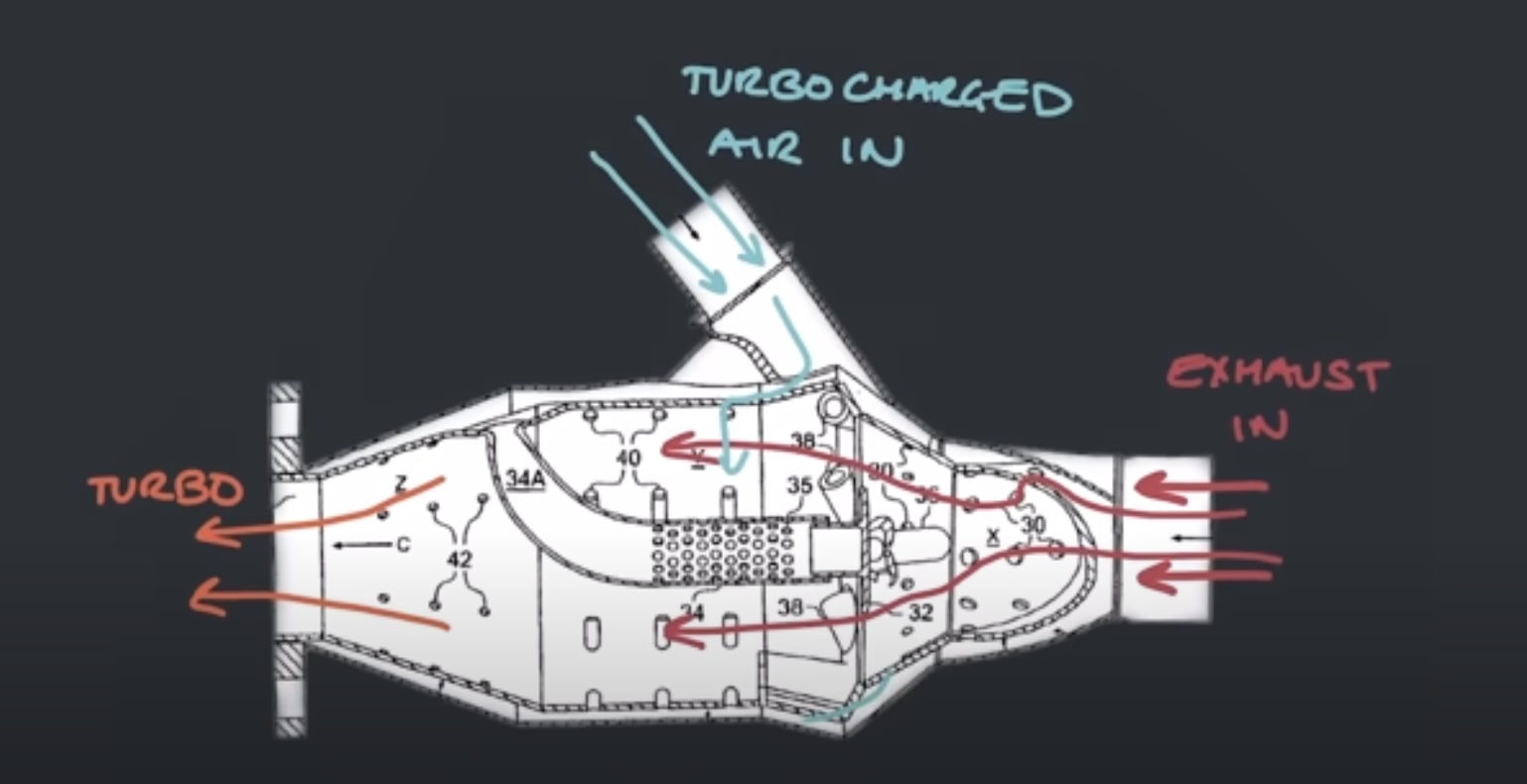

Toyota drew inspiration from Formula 1, where teams in the 1980s burned fuel in the exhaust to spin the turbo even when the throttle was closed. By tweaking the engine control unit (ECU), they allowed air and fuel to bypass the engine and ignite in the exhaust manifold. This kept the turbo spinning, ensuring boost was ready when the driver hit the throttle.

The result? The dramatic pops, bangs, and flames that became synonymous with rally cars.

Subaru’s Rocket Exhaust

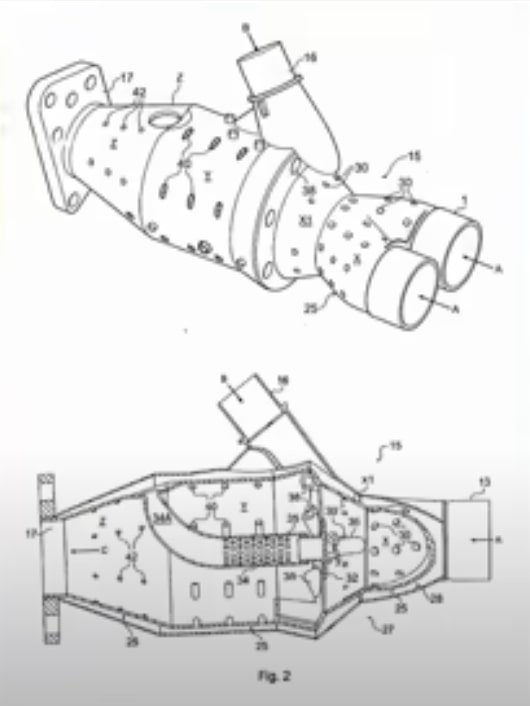

Subaru took anti-lag to another level with its “Rocket Exhaust,” a device as revolutionary as its name suggests. Sitting between the engine and the turbo, the Rocket used precision engineering to create a controlled, consistent flow of high-energy pulses.

Here’s how it worked:

- Fresh, compressed air was routed into the exhaust via a valve.

- Exhaust gases and air mixed in a chamber designed to maximise combustion efficiency.

- The intense heat ignited the air-fuel mixture, creating a high-velocity gas stream to spin the turbo.

This system, made from heat-resistant materials like Inconel, was more efficient and reliable than traditional anti-lag. By reducing temperatures and wear, it extended turbo life and improved drivability.

The Drawbacks of Anti-Lag

Despite its benefits, anti-lag came with challenges. The intense heat often melted turbos and exhaust manifolds, requiring teams to carry spares. Fuel consumption skyrocketed, forcing cars to carry heavier fuel loads.

Drivability also suffered. Traditional engine braking disappeared because the engine continued firing even when the driver was off the throttle. Drivers had to rely more on mechanical brakes, which wore out faster.

Toyota’s Fresh Air Anti-Lag

In response, Toyota introduced Fresh Air Anti-Lag. By routing intake air directly into the exhaust, this system burned cleaner and cooler, reducing stress on components. It was more fuel-efficient and allowed for precise ECU control, making it a game-changer for reliability and performance.

Legacy and Impact

Anti-lag cemented itself as one of rallying’s most iconic innovations, delivering the instant throttle response needed for tight, unpredictable stages. Although modern regulations have limited its use, its influence remains, inspiring technologies like hybrid turbo systems in today’s motorsport.

From Subaru’s Rocket Exhaust to Toyota’s Fresh Air system, anti-lag’s evolution showcases motorsport engineering at its finest – transforming challenges into thrilling solutions. And yes, the flames and bangs are an added bonus for fans and drivers alike.