In the world of Formula 1, innovation often pushes engineering to its limits. One of the most audacious examples is the BRM H16 engine, a design so ambitious it bordered on madness. In the mid-1960s, when other manufacturers focused on conventional V8s or V12s, British Racing Motors (BRM) introduced an engine that redefined complexity – a three-litre H16.

Why Build an H16?

The decision to design an H16 engine was born out of the shifting landscape of Formula 1 regulations. In 1965, engine capacity was limited to 1.5 litres, producing modest power outputs of 150-225 horsepower. BRM’s 1.5-litre V8 excelled within this framework, focusing on efficient combustion and lightweight engineering.

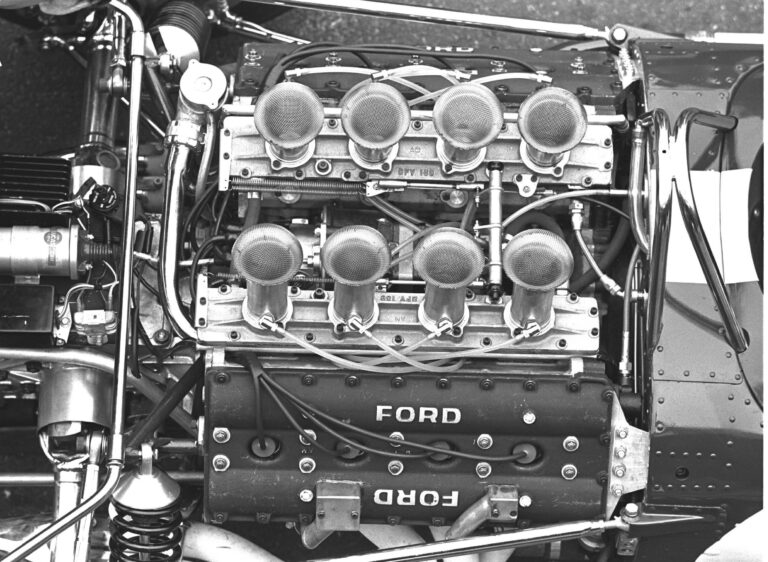

In 1966, the regulations doubled engine displacement to 3 litres, drastically increasing power potential. Teams scrambled to redesign their power units. Ferrari opted for a V12, while McLaren used a Ford V8. BRM, however, aimed higher. They considered a V24 but found it impractical due to size constraints. Settling between 12 and 16 cylinders, BRM decided to stack two flat-eight engines into a single H16 unit.

The H16 Architecture

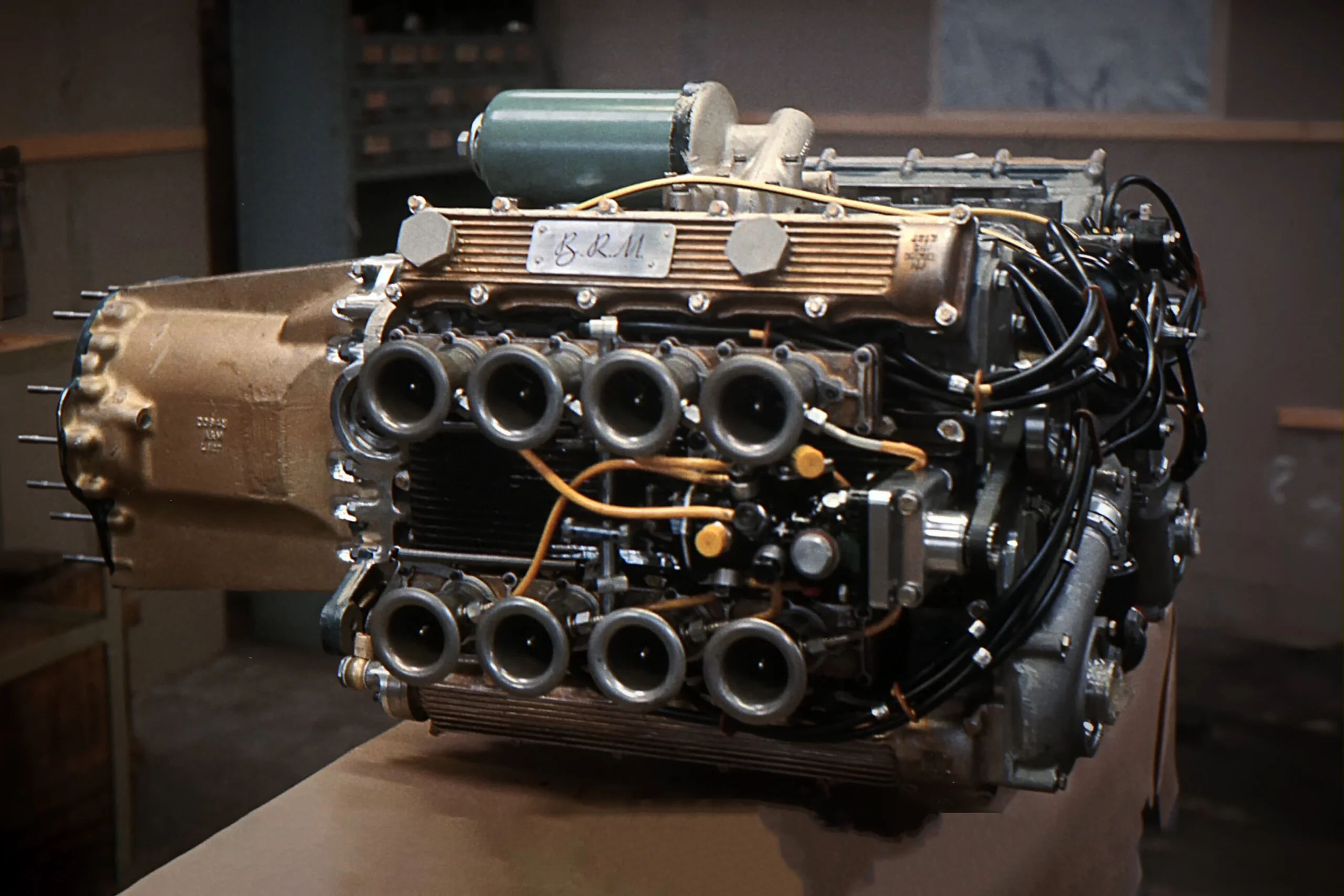

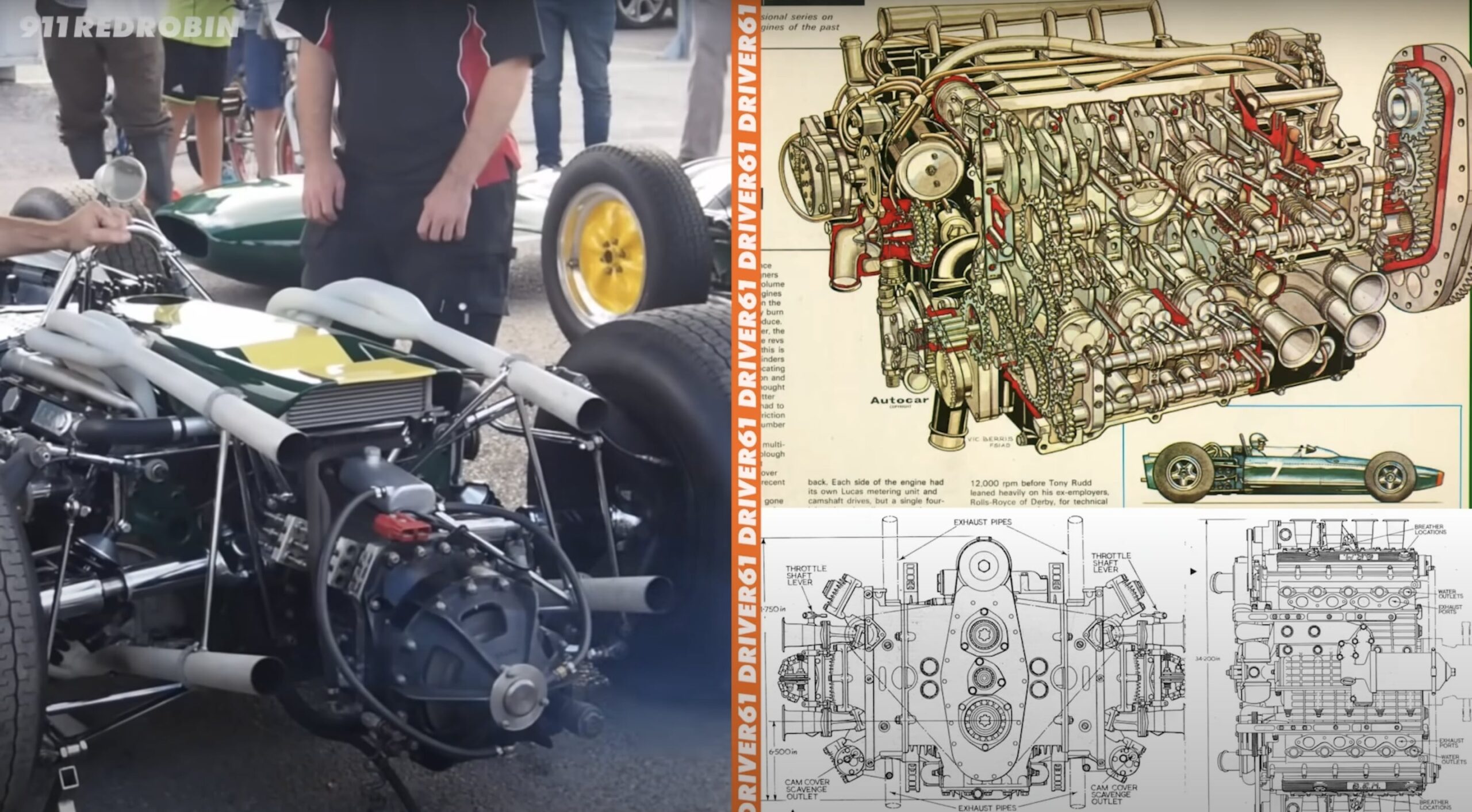

The H16 engine’s design was both innovative and intricate. It combined two flat-eight engines, stacking them to form a configuration resembling the letter “H.” Each flat-eight came from BRM’s successful 1.5-litre V8, flattened and fused with another. This compact design offered a shorter engine length than a V12 and allowed for greater power output.

However, combining two engines introduced immense mechanical complexity. Two crankshafts required synchronization, achieved through an idler gear. The engine also had eight camshafts, 64 valves, 16 throttle bodies, and dual oil coolers, making it one of the most complicated engines in motorsport history.

Engineering Challenges

The complexity of the H16 engine posed significant challenges. Cooling was one issue, requiring two water pumps and interconnected coolant channels to maintain proper temperature. The oil system, too, had to manage the demands of dual engines, using almost twice the oil of its competitors.

Moreover, the engine’s weight became a major drawback. Initial estimates placed the engine at 170 kg, but it ultimately weighed 250 kg – nearly double that of Ferrari’s V12. Its high centre of gravity and increased fuel consumption further compromised the car’s handling and agility.

Reliability was another Achilles’ heel. The engine suffered from vibration issues due to the crankshaft design, causing components to fail. Attempts to counteract this with weighted cranks led to even more problems, as detached weights caused catastrophic failures during races.

The BRM H16 in Action

Despite its flaws, the BRM H16 managed a brief stint on the grid. It achieved a single victory at the 1966 United States Grand Prix at Watkins Glen, powering a Lotus 43. However, its tendency to overheat, guzzle fuel, and blow up made it an impractical solution for Formula 1’s demands. By 1968, BRM abandoned the H16 in favour of a more conventional V12.

Legacy of the H16

The BRM H16 is remembered as a testament to Formula 1’s spirit of innovation and risk-taking. Although it was plagued by reliability issues, its design showcased the limits of what could be achieved with mid-century engineering. Today, it stands as a fascinating chapter in the sport’s history, celebrated for its ingenuity and the lessons it taught engineers.