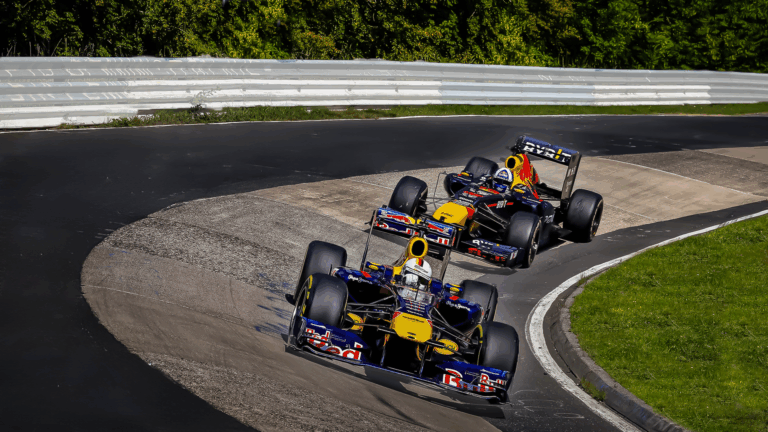

The sound of Formula 1’s V10 engines is unforgettable. These engineering masterpieces, raw, powerful, and capable of astonishingly high revs, are often considered the pinnacle of engine design in motorsport. But how did they manage to exceed 19,000 RPM? And why are they no longer a part of modern F1 cars? Let’s delve into this iconic era of Formula 1 engineering.

The Beginning of the V10 Era

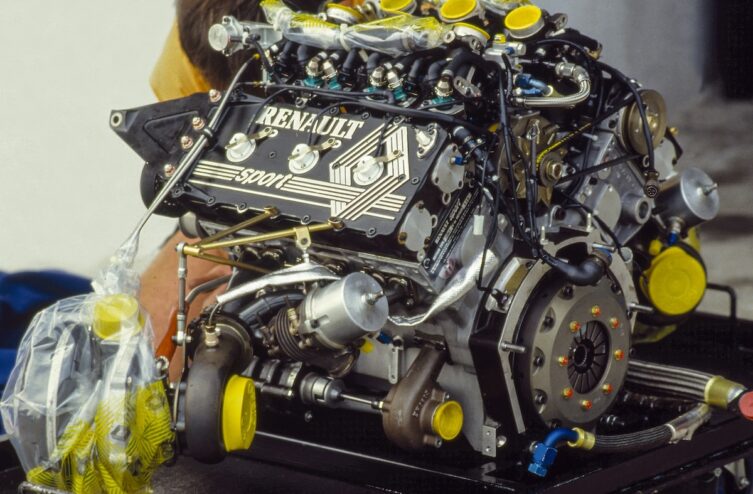

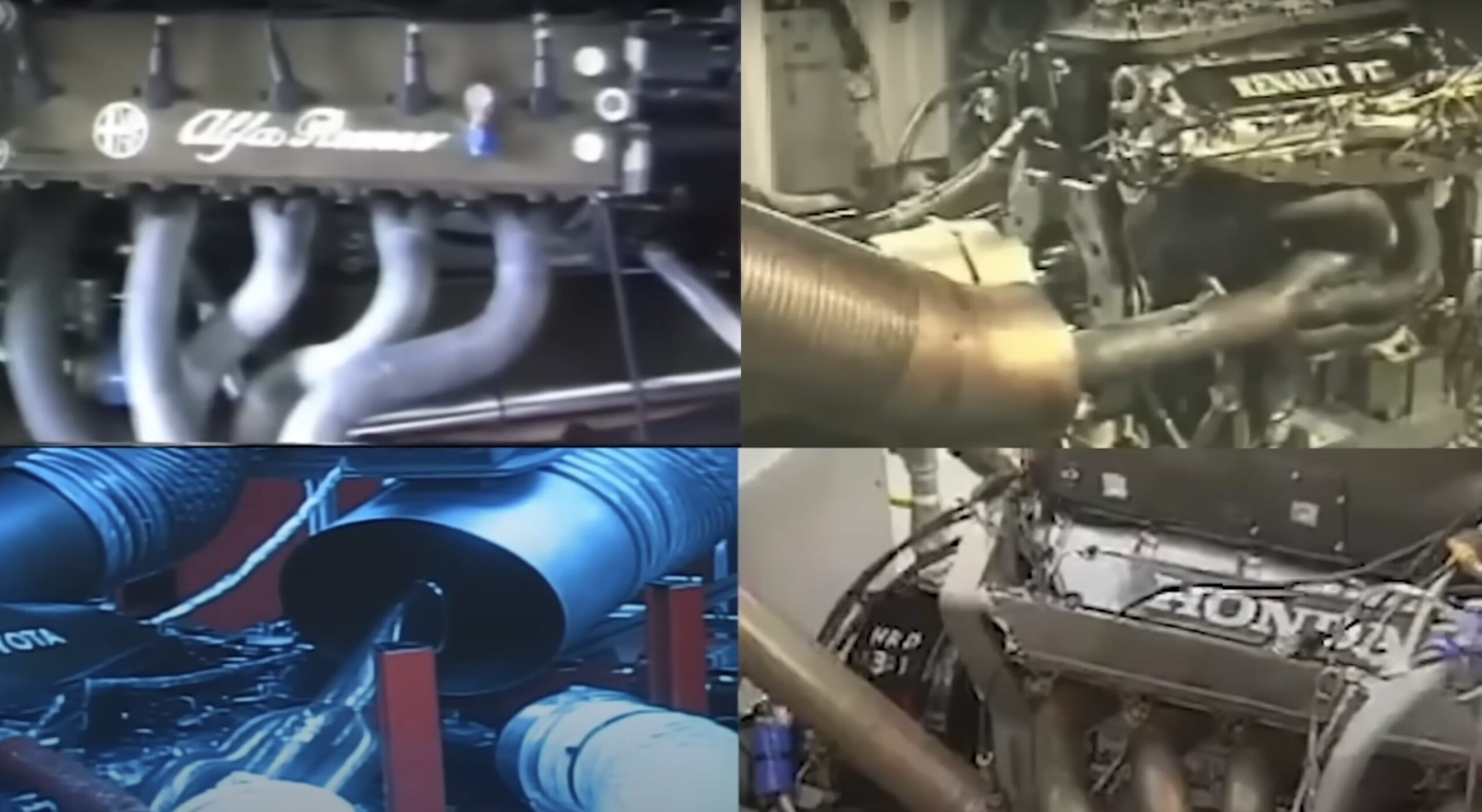

The V10 engine era began in 1986 with Alfa Romeo’s 3.5-litre unit but only truly gained momentum in 1989, thanks to Renault. Back then, engine regulations offered significant freedom, with a key restriction: engine displacement was capped at 3.5 litres, and turbochargers were banned.

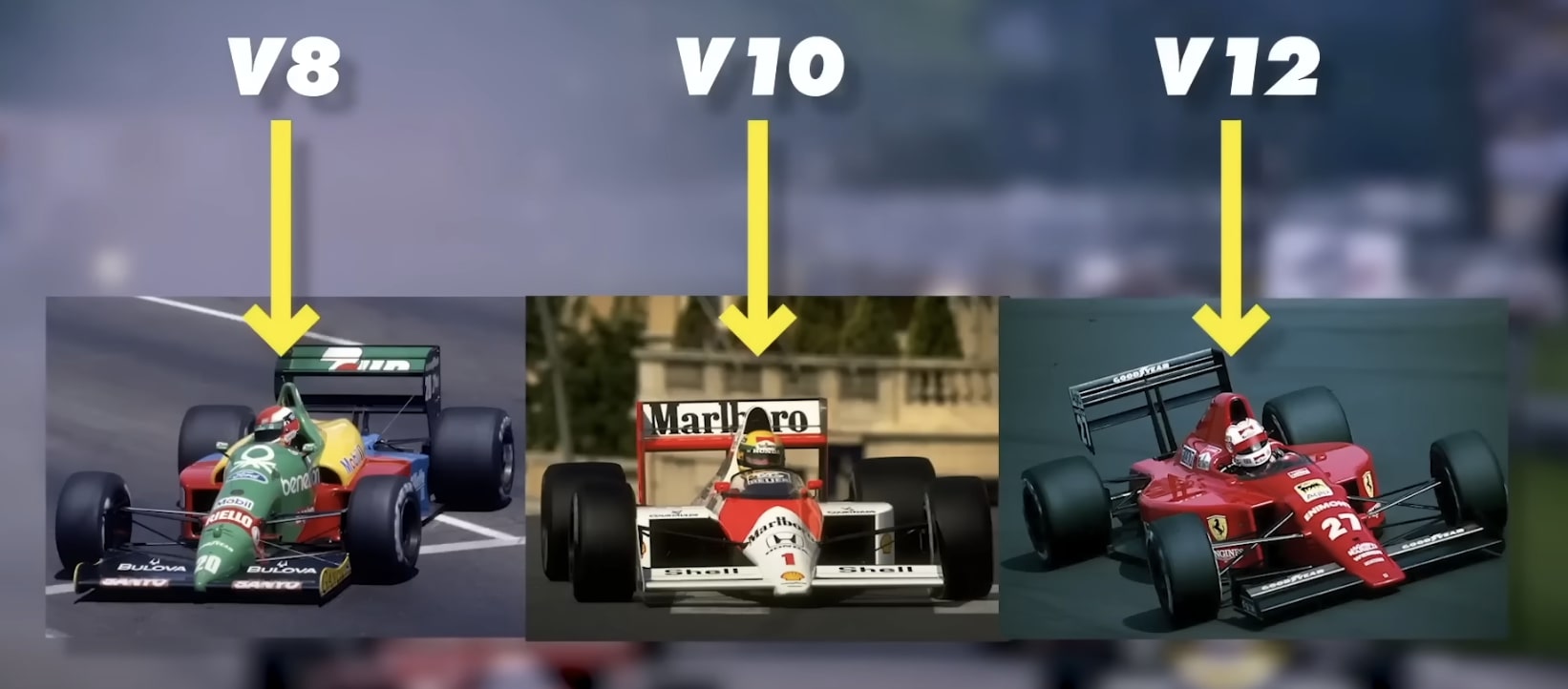

This period saw a mix of engine configurations on the grid, including V8s, V10s, and V12s. At one point, even a W12 was attempted, though it never qualified for a race. Each manufacturer championed their design:

- V8s: Preferred by Ford for their simplicity and relative fuel efficiency.

- V12s: Ferrari embraced this configuration, prioritising maximum power and ignoring complexity or cost.

- V10s: Renault struck a balance, finding a sweet spot between power, weight, and efficiency.

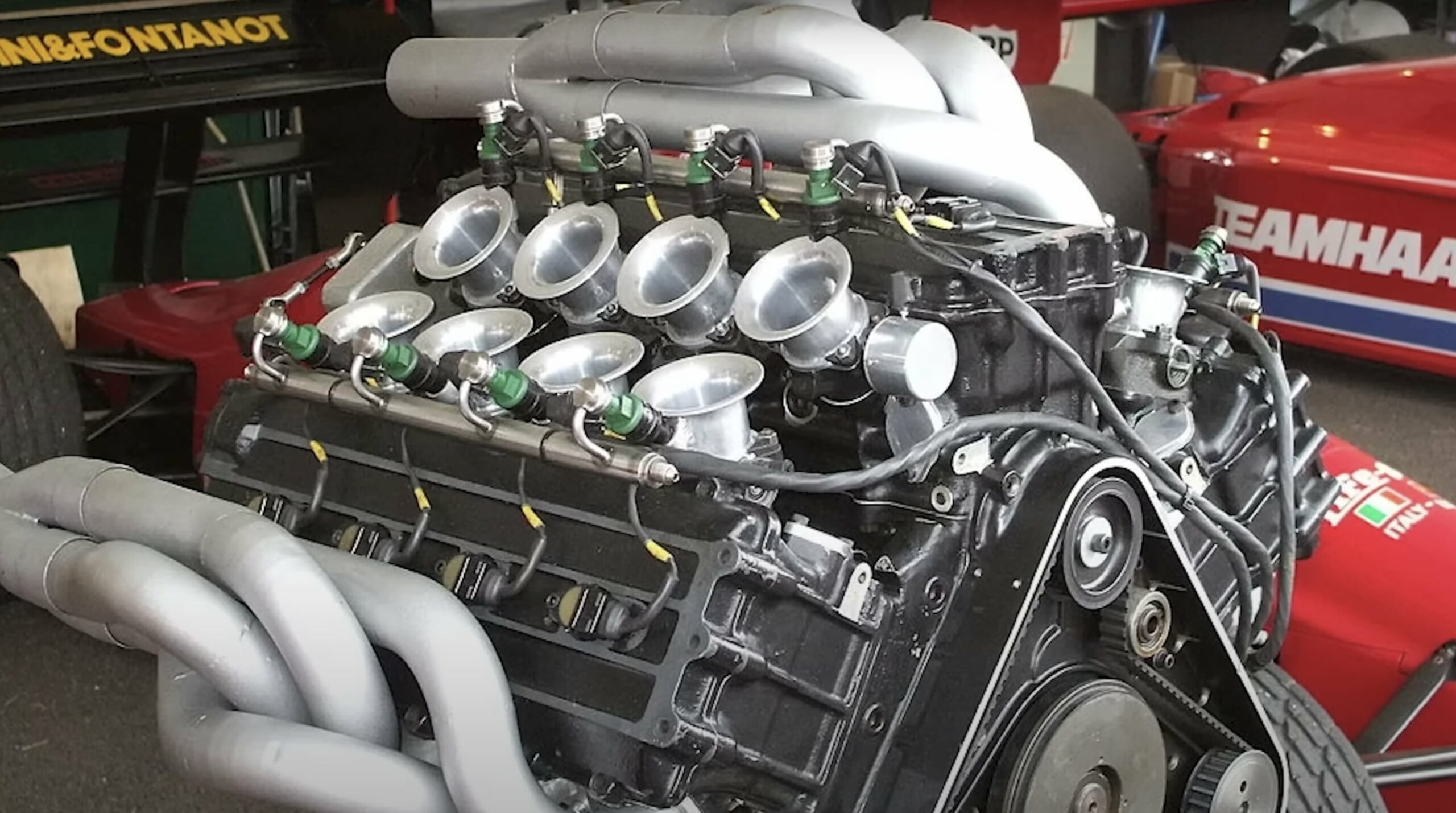

How V10s Reached Such High RPMs

The key to increasing power in a naturally aspirated engine lies in the formula: Power = Torque × RPM ÷ Constant. With displacement capped at 3.5 litres, manufacturers couldn’t increase torque significantly. Instead, they focused on raising RPM. But achieving this required overcoming major technical challenges.

1. Durability of Moving Parts

In conventional engines, pistons, connecting rods, and crankshafts are engineered for a specific speed range. Exceeding these limits risks catastrophic failure due to extreme stresses. For example, at high revs, pistons can reach speeds of 70 mph within the engine, generating forces that stretch connecting rods by up to a millimetre per stroke.

2. Valve Float

Traditional valve springs struggle at high speeds, leading to a phenomenon called valve float. This occurs when valves fail to return to their closed position quickly enough, potentially causing a piston to collide with a valve—a failure that can destroy an engine.

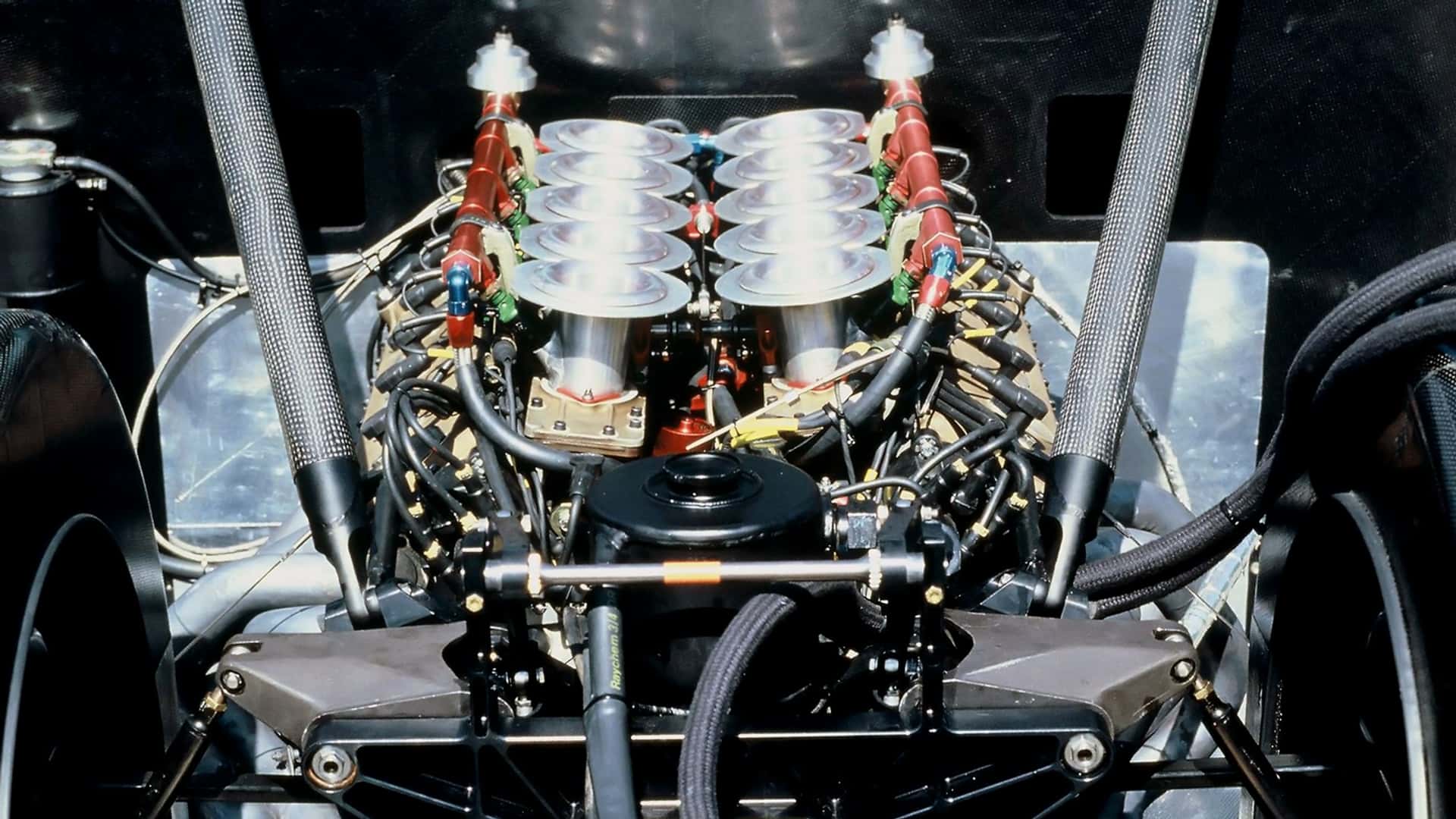

To solve these issues, engineers introduced pneumatic valve systems, replacing springs with air pressure for more precise control. Exotic materials such as titanium, aluminium, and beryllium were also employed to reduce weight and enhance durability.

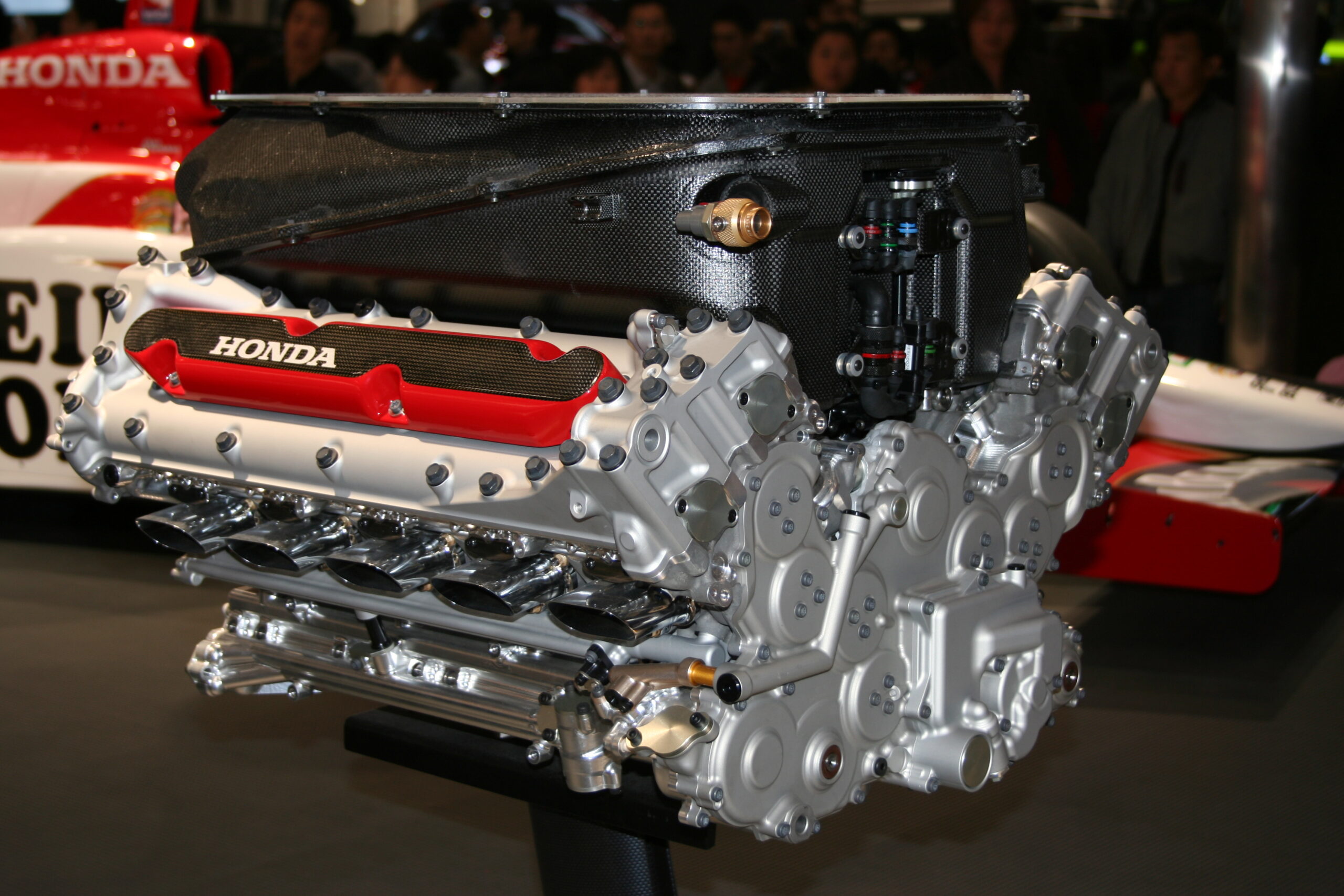

The Advantages of the V10 Over Other Configurations

The V10 offered distinct benefits compared to V8s and V12s. With two additional cylinders over a V8, V10 engines could use smaller, lighter pistons, reducing rotating mass and enabling higher revs. While V12s also used small pistons, their additional components increased complexity and weight, limiting their maximum RPM.

One of the V10’s most celebrated characteristics was its sound. Unlike the balanced hum of a V12, the V10’s uneven firing order produced a unique, thrilling note that resonated with fans worldwide.

The Decline of the V10

Developing V10 engines capable of such extreme performance came at a cost. Teams spent millions on advanced materials and precision manufacturing to withstand the high RPM and intense vibrations. This made engine development prohibitively expensive for many manufacturers.

In 2006, the FIA introduced 2.4-litre V8 engines to reduce costs and attract new manufacturers. Although these engines initially retained high rev limits, subsequent regulations gradually reduced maximum RPM to today’s limit of 15,000. While this shift has improved sustainability in Formula 1, it marked the end of an era defined by the raw power and thrilling acoustics of V10 engines.