This car goes from 0-62 miles per hour in 0.956 of a second.

This is the classic acceleration test, one that we all grew up using to compare cars.

A Formula 1 car will do it in about two and a half seconds, the fastest production car – a Rimac Nevera – will do it in 1.7 seconds, and my trusty old VW Passat will do it in about 8.

But a group of students from AMZ Racing based at the Swiss university, ETH Zurich, made a car accelerate faster than anything else in the world – and smashed through the previous record of 1.46 seconds.

So, I spoke with Eloi Roset from AMZ Racing to understand exactly how these ambitious students approached this crazy project, what challenges they needed to overcome and how they engineered a car that accelerates more than twice as quickly as an F1 car.

This record – which is actually 0-100 kilometres an hour – is one that’s been battled over for a long time, last being broken in 2022 by the University of Stuttgart – at 1.461 seconds.

The teams typically use the base of a Formula Student car. And if you didn’t know, Formula Student is fantastic – it’s an educational engineering competition where students from around the world design, build, test, and race formula-style racing cars.

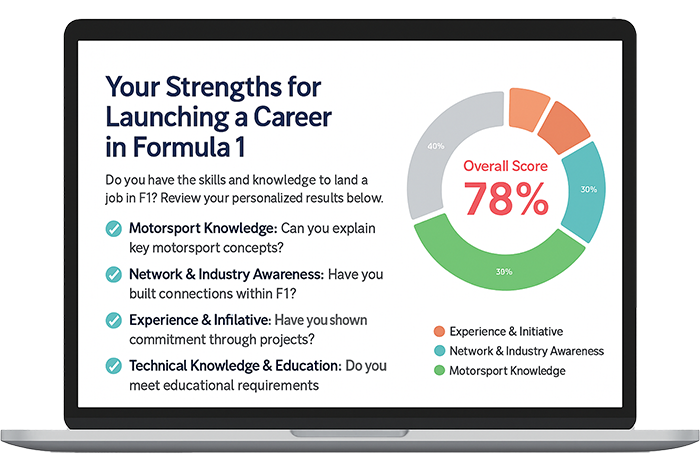

The aim is to give students experience in practical engineering, as well as teamwork and project management. And it’s many of these students who end up working in Formula 1.

AMZ Racing used the base of the Formula Student car as it’s light and has a small frontal area (which is good for low drag), and they also had one available!

But, it wasn’t a case of just adding more power to an existing Formula Student car, Eloi explained:

“The problem is you don’t design a Formula Student car for this kind of loads because, at the current record, you have to put like really high loads on all the suspension parts for the aerodynamic force. The power that you need is much higher than for racing competitions so you have to modify it very heavily.”

And AMZ Racing’s target wasn’t just to beat the old record, they were ambitious, and they wanted to break the one-second threshold. That’s over 30% faster than the previous record – a huge amount.

Put simply, this project is all about three things. Having enough power to accelerate quickly, having enough grip to transfer that power through the tyres into the asphalt and making the powertrain, chassis and suspension strong enough not to bend or break while doing it.

So, in order to get to their target, they needed a car that was stronger, had more grip and was more powerful. To plan out such an ambitious project, the team needed to go back to the drawing board and figure out what was really required.

And as you might have guessed, their standard Formula Student car was not up to the task. So, the team stripped everything from this car and were only left with the tub, the seat, the tyres and a few other bits.

But, their main focus was going to be on grip and power and a surprising loophole in the rules, which I’ll explain later.

Acceleration needs grip from the car’s floor

So, first, let’s talk about the grip. The most interesting part here is the car’s floor. As we know, a lot of the downforce of formula-type cars comes from the floor.

Typically, the air flows under the car, and gets accelerated, causing an area of low pressure which sucks the floor towards the ground. This means the tyres are pressed into the track harder, and so gives the car more grip.

And that works pretty well, but it’s by no means the best way to add downforce to a race car.

But the problem with race series – at least for engineers – is that they have rules, and over the years, regulators have banned various types of design that create downforce.

A few examples include flat floors – banned in 1994 after Senna’s death, side skirts banned in the 80s and the famous Brabham fan car which was withdrawn from competition in 1978.

But, for the 0-100 world record, there are no such rules. And so the team’s first port of call for generating more grip was the floor and plenty of fan-assisted downforce.

And the concept is pretty simple.

“We put a fan on the floor. We put some skirts around it to seal it.”

Eloi Rosset – AMZ Racing

The fans here are doing the same job as “organic” aerodynamics – creating low pressure under the car to suck it down into the ground. But why are fans more effective than normal aero?

Well, a couple of reasons. First, you can place the fans wherever you want, changing the centre of pressure. Second, you can control the fan speed, therefore controlling the amount of downforce.

And most importantly, where normal aero needs the car to be moving to work, fans don’t. And when trying to break a record that begins from a standing start, that’s very important. You can have maximum downforce at zero miles per hour.

But, things do get more complicated as the car starts to accelerate. In a traditional formula car, the underside is a bit like an upside-down aeroplane wing sucking the car to the track. With this type of underfloor, more speed, and more air means more grip, but the AMZ Racing car is slightly different.

The floor is completely flat; there’s no diffuser. It’s basically a flat rectangle of carbon between the four wheels.

And as there’s no diffuser to speed up the air while the car is moving. It means that the floor itself is not creating any downforce. Instead, we have the fans.

And while static, this works incredibly well. The skirts on the side of the floor seal it to the ground, and the fans easily remove enough air to suck it down and load up the tyres – which is great for the initial getaway.

But, when the car starts moving, more air comes in the front of the floor, meaning the pressure under the floor isn’t as low… and so there’s less grip.

And there are other issues. As soon as the car starts moving, the defects and bumps in the track surface mean the seal isn’t as good and allow air from outside the floor to leak in and so reduce suction.

So, with air rushing in at the front of the floor and air leaking in from the side, the team needed more fan power! But with so many unknowns, it was difficult to know exactly how many fans were required.

“So we kind of over-killed it, we planned to put like six, eight fans and at the end we worked with only two.”

Eloi Rosset, AMZ Racing

As for the skirts that seal the sides of the floor, these are made from shaped carbon fibre that rub along the floor in order to offer the very best seal. Now, of course, that means they wear out pretty quickly, but they’re so important to the grip that the team just changed them out when needed.

Suspension for the fastest accelerating car

So, on to the suspension. As this was a straight-line record, you might think that the suspension isn’t that important; after all, there aren’t any corners.

However, the suspension and the control of the floor height have a big effect on the downforce generation. Remember, most of the grip comes from the floor and fans, and if the seal at the edge of the floor is broken, we lose a lot of grip.

Imagine the AMZ Racing car with a really soft suspension. The car accelerates away from standing at 3G, and the load going through the suspension is huge. The rear suspension compresses, and the front suspension lifts.

But the issue here is the car’s floor. It’s gone from being perfectly parallel with the ground to the rear of the floor being much closer than the front. And, with a larger gap, it will leak pressure, reducing the car’s grip.

So, what’s the solution? Well, maybe you’d think that as we’re not going around any corners, we don’t really need suspension – that maybe you could make the suspension solid, like a go-kart. This is actually something that Willaims F1 tried in the 80s, but that’s another story.

The problem with this is that even going in a straight line, you still need some suspension to absorb the initial acceleration and small bumps in the track surface.

Otherwise, you’d only have the tyre acting as the spring. And without any damping, the car would likely bounce awkwardly down the track. And if it’s bouncing, it’s also breaking the seal down the side of the floor.

So, the suspension needs to be stiff enough to deal with about 200 kilograms of downforce but soft enough to deal with any vibrations and bumps.

So, the answer was simple…

“a fully multi-couple suspension with hydraulically connected components.”

Eloi Rosset, AMZ Racing

You might have heard of hydraulically connected suspension, or FRIC – Front to Rear Interlinked Suspension – as it was called in F1. It’s not an active suspension like we saw in F1 in the 90s, but a passive system that works by hydraulically connecting the front and rear suspensions.

This linkage helps maintain a consistent ride height and car attitude under different conditions like acceleration, braking, and cornering.

The system was first introduced in Formula 1 by the Mercedes team and their then-technical director, Aldo Costa. This innovative suspension system, debuting around 2011, represented a big development in F1 but was banned by the FIA in 2014.

Anyway, this system allows the AMZ Racing team to keep the suspension supple enough to absorb bumps but stiff enough, especially under acceleration, to keep the car’s floor correctly aligned with the ground.

What tyres Did It Use?

So, we have the downforce, we have the suspension… just the tyres, powertrain and that little loophole to go.

When I spoke with Eloi, I expected the team to be using some super-soft, custom-made, tackier-than-blue-tack type of tyre. However, the team just used the standard Formula Student competition tyre, the Hoosier LC0 (zero).

I also expected the team to use low tyre pressures like those used in dragster races to achieve maximum grip. However, they did not deviate too far from the standard tyre pressures.

This decision makes sense because the tyres are not solid, and they compress under pressure, which, again, affects the distance between the car’s floor and the ground. As we’ve mentioned many times, this distance is crucial for optimal performance of the floor.

However, although they ran quite standard tyre pressures, the relative pressure was essentially lower. Because there’s more vertical load going through the tyres, the same tyre pressure means the tyre is being squashed more.

How was the world’s fastest accelerating car powered?

So, onto the powertrain. With acceleration being the thing here, of course, the car is four-wheel drive. And to me, this is one of the most interesting innovations in Formula Student.

“our usual Formula Student cars have four motors, so one on each wheel. We have traditionally in our team to self-design the motors ever since the beginning of the electric class in 2009.”

Eloi Rosset, AMZ Racing

Yes, each wheel has its own tiny motor that weighs around 3 kilograms. The car has no differential, no driveshafts and no gearbox – which means you can control the torque to each wheel individually, but more on that later.

A typical Formula Student car is restricted to 80 kilowatts of power – about 107 brake horsepower. But the team knew that this wasn’t going to be enough, so they set sights on doubling the power.

As the rear of the car has the most grip, thanks to weight transfer and the position of the car’s floor, the rear tyres have more grip than the fronts. And so, this was the area for development.

“We redesigned at the back, which is where we could use most of the potential. And we basically doubled the power. So we made a completely new version of the motors. We just made it a bit longer, put double the torque and yeah, we just put them in.”

Eloi Rosset, AMZ Racing

The launch

So, the car has enough power, but how is that power controlled? Remember, this acceleration is insane – less than a second to 62 miles per hour.

Get some wheelspin, have a slide, and the car has spun, or worse, before the driver has even realised. Now, that’s the worst-case scenario, but what’s more relevant is how a human driver would maximise the grip on each individual tyre.

With reaction times of about two-tenths of a second and an inability to control power to each wheel individually, there’s no way a human can get the most from a launch. So instead, the driver just puts his foot to the floor, and then the computers take over.

“you just have to tell your body like, whatever happens, pedal to the floor and see you at the end”

Eloi Rosset, AMZ Racing

There’s a lot going on under the bodywork here in order to direct the perfect amount of torque to each of the wheels.

The first task is for the control system to understand the speed of the car, and for that, it uses a speed-sensing laser that you might have seen in F1. It points at the ground and measures 200 times per second.

Then the car has a sensor on each individual wheel. That way, the system can compare the speed of the car against the speed of each individual wheel and, so, calculate if any of the wheels has wheelspin.

Once it knows this, it will allow each wheel to slip up to a certain calculated point, but if the slip increases too far, then the torque will be reduced to this individual wheel – allowing the slip to reduce and keeping the car on the straight and narrow.

And all of these calculations have to be applied very quickly and very precisely.

“It’s quite tricky because you can have quite big accidents if something goes sideways. It’s something that in testing when we were at lower power, we also saw that, okay, if something’s not safe, it gives you quite a big… I don’t know how to say that, but it’s a bit scary from the outside.”

Eloi Rosset, AMZ Racing

The day of the record

So, what happened on the day of the world record itself?

Let’s talk about the choice of location first, and this is where the team found a great loophole in the rules. I would have thought that a downhill piece of asphalt would be the best option for this record, and it likely would be, but the rules don’t let you do that.

So, the next best option is a perfectly flat track, right? Well, actually, no.

The world record rules state that if running on a flat surface, the car must complete the run twice, in both directions. Then, the average time of the two runs is taken for the official record.

However, the AMZ team obviously have a great future in Formula 1, as they found a better way around the rules. If the run is uphill, just a little, only one run is necessary.

“when we broke the record in 2016, I checked the data and I checked the times because they did, I think 10 runs in a row or maybe a bit more. we saw that the variability was up to half a tenth of a second. So that’s quite a lot for all the effort that you do to get that fast. So then we said, hey, if we can do only one run slightly uphill, it’s better than having the variability”

Eloi Rosset, AMZ Racing

Yes, they needed to drive uphill slightly, which is slower. But it meant they could really push on one run and not need to worry about replicating that same speed. And for the team, it was more than worth it.

Conclusion

So, if you have the engineering mindset, you might be asking yourself, why didn’t they go faster?

Remember, this record was about the combination of power, grip and making sure the car didn’t break. And it seems that was the limiting factor.

“we saw that the limitation that we had was on one side, the structural integrity. At some point, the chassis cannot deal with more loads.”

Eloi Rosset, AMZ Racing

Eloi mentioned that they could have turned up the fans, and they could’ve had a bit more power, but next, the tub or suspension would’ve likely broken.

And designing and building a brand-new chassis is just very expensive – both in terms of time and money.

The team managed to smash through the previous record and break through the one-second barrier – and at some point, these projects unfortunately need to stop.

“So we, we achieved that. So at that point you have to also get back to normal life.”

Eloi Rosset, AMZ Racing

Thanks to AMZ Racing for the help with this video and Eloi for the interview, which you can watch in full on Driver61’s Podcast channel and all podcast platforms.