F1 brakes can stop a car from 200 mph to 60 mph in just three seconds, and the entire Brembo braking system costs just under £100,000. But there’s remarkable engineering behind this price tag – from raw aluminium blocks to carbon fibre that withstands temperatures of 1,000°C, the same as molten lava.

The manufacturing process begins with topological optimisation software that determines exactly where material is needed for stiffness and removes everything else. Each F1 calliper starts as a solid aluminium-lithium billet – a material choice mandated by F1 regulations to prevent teams using exotic or dangerous materials like beryllium, which is toxic when machined.

What’s striking is how much material gets removed during machining. A huge portion of the original block is carved away, leaving only the essential structure. The callipers are machined from single pieces with no welds or joints that could create weak points. Inside, six titanium pistons handle the massive pressures, chosen because titanium offers an exceptional strength-to-weight ratio and heat resistance.

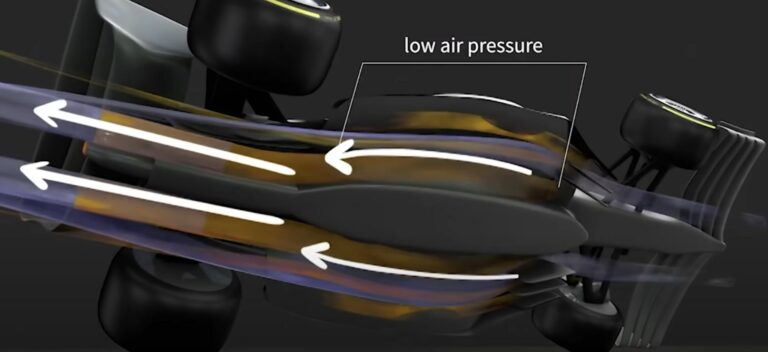

The carbon-carbon discs follow an even more fascinating process. They begin life looking like thick felt – soft, fuzzy material that bears no resemblance to the final product. Through a mechanical needling process, the carbon fibres are pressed into their axial direction, controlling how the disc will handle heat dissipation.

Two crucial oven processes transform this felt into the final disc. First, carbonisation creates a fragile, porous structure. Then methane gas is introduced in a second oven, where carbon from the gas fills the pores whilst hydrogen is burned off – hence the term “carbon-carbon”. This entire process takes up to three months just to create the basic disc blank, with another four weeks for finishing.

The precision required is extraordinary. Modern F1 discs contain up to 1,200 cooling holes, each a minimum 3mm in diameter as required by regulations. Machining tolerances are held to 0.02mm – thinner than a human hair. The wear rate achieved is remarkable: just 0.01mm per kilometre, meaning brake pads might only wear 1mm during an entire race weekend.

Every component undergoes 100% quality inspection using optical measuring systems that create detailed 3D models. Before leaving the factory, components are tested on dynamometers that replicate exact race conditions, often exceeding what they’ll face in actual races. The service cycle sees callipers returned every 10,000km (roughly three Grand Prix weekends) for complete rebuilds using augmented reality workbenches that log the precise torque of every bolt.