Alpine F1’s front wing manufacturing process reveals why these aerodynamic components cost millions to develop and take seven full days of round-the-clock precision work to build. Each front wing generates 20 to 30% of an F1 car’s total downforce whilst controlling airflow over every other part of the vehicle.

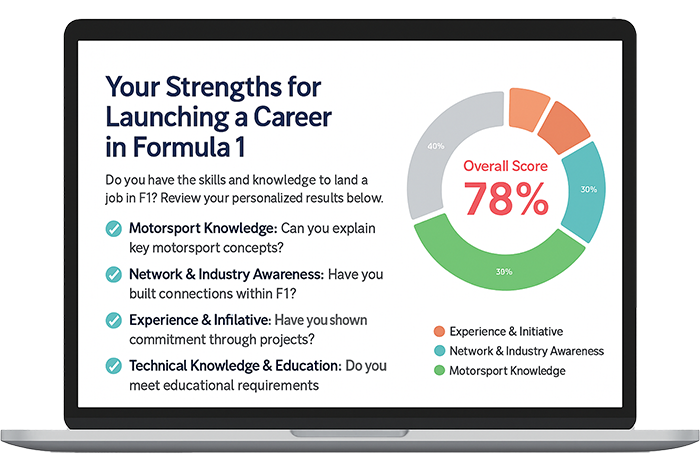

The manufacturing journey begins with pages of technical regulations from the FIA, specifying exact shapes, curves and boundaries for every component. Alpine’s aerodynamicists work within these constraints using CFD simulations – limited to 2,000 runs every couple of months – before validating designs in the wind tunnel with real airflow over physical models.

The actual construction process involves hundreds of individual carbon fibre pieces, cut by computer-controlled systems and laid up by teams working day and night shifts. Alpine uses sophisticated laser projection systems to ensure each layer is positioned perfectly – a critical step since the first layer determines the entire wing’s structural integrity.

After layup, wings are vacuum-bagged and cured in pressurised autoclaves before undergoing rigorous crash testing with Cranfield University. The FIA requires each wing to slow a car gradually without exceeding 40G of force, protecting drivers whilst maintaining structural performance under aerodynamic loads, jacking forces, and curb strikes.

The entire process demonstrates how F1 teams balance extreme precision with cost cap constraints, creating components that must deliver maximum performance whilst surviving multiple race weekends.